FEELER VB-1900A

Choose from the smallest to the largest model that meets your various demands for today’s production. No matter which one you select, you get the same FEELER tradition of quality and excellence.

► The machine structure and major parts are manufactured from Meehanite cast iron for outstanding material stability, thereby assuring long-term, deformation-free performance.

► The entire machine construction is subjected to ANSYS and NASTRAN Finite Element Analysis to achieve optimum rigidity and stability.

► Heavy duty construction throughout, combined with extra

stable base, supported by 8-16 foundation bolts.

► Box ways on X, Y, Z axis.

FEELER VB-2200A

Choose from the smallest to the largest model that meets your various demands for today’s production. No matter which one you select, you get the same FEELER tradition of quality and excellence.

► The machine structure and major parts are manufactured from Meehanite cast iron for outstanding material stability, thereby assuring long-term, deformation-free performance.

► The entire machine construction is subjected to ANSYS and NASTRAN Finite Element Analysis to achieve optimum rigidity and stability.

► Heavy duty construction throughout, combined with extra

stable base, supported by 8-16 foundation bolts.

► Box ways on X, Y, Z axis.

FEELER HV Series

Creating a New Level of Parts Machining and Precision Mold Machining

For years, FEELER had dedicated itself to the pursuit of higher efficiency and higher performance vertical machining centers to help customers stay competitive. FEELER’s HV Series was designed to integrate many innovative features into the existing models.

The HV Series features outstanding machine structure, accuracy, and machining efficiency, greatly surpassing existing models. It is an excellent machine especially ideal for today’s high speed part machining.

QUASER MV134

The new vertical machining center, MV134, is designed to meet the goals of high efficiency with compact floor space. The MV134 retains the high rigidity and high accuracy features of all the MV1 series products. High precision linear guideways are used in all three axes and X/Y/Z travel as 26” x 22.5” x 22.0”.

The MV134 design offers excellent operator accessibility and is easy to operate, giving you more flexibility in the use of space for more efficient production

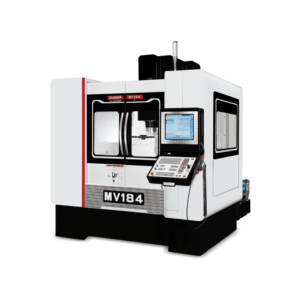

QUASER MV184

The MV1 series machines have a legendary history of high quality and proven performance, the New MV184 series has an even greater degree of reliability and performance. The design concepts of the new MV184 series combine advanced technology, performance and value for various machining applications.

Quaser produces this machine layout with the state-of-the-art digital design. Taking into consideration easy repair to reduce downtime. The MV184 series is the choice to increase part production.

QUASER MV204 / MV205

The MV2 series offers a wide line-up of machines with X axes travels of 1,270 mm (50 inch) to 2,040 mm (80 inch) and various spindle speeds and drive configurations to allow the user to machine a wide range of workpieces.

To meet different processing needs, we offer a variety of machine and control specifications to choose from. In addition, the user-friendly control panel design has improved the customers operating convenience.

QUASER MV214 / MV215

The MV2 series offers a wide line-up of machines with X axes travels of 1,270 mm (50 inch) to 2,040 mm (80 inch) and various spindle speeds and drive configurations to allow the user to machine a wide range of workpieces.

To meet different processing needs, we offer a variety of machine and control specifications to choose from. In addition, the user-friendly control panel design has improved the customers operating convenience.

QUASER MV234 / MV235

The MV235 is able to cope with high-speed machining and high strength material machining, The MV235 combines high speed, high torque and high chip removal rates to achieve stable high-precision machining.

The 4 large linear guides of Y-axis are designed and installed on a one piece base to obtain high rigidity and stability. The extra wide column with it’s unique shoulder is designed to maintain column rigidity and geometric accuracy against the weight of the tool magazine.

The machine internals are equipped with a 6 piece auger system combined with an external lift up chip conveyor and coolant wash to best manage the chip disposal.

FEELER U600

Intelligent Machining Function

The U-600 employs anti-chatter technology of “Chatter Lobe” program, which predicts and prevents occurrence of chatter during machining. Users need to simply input parameters into Chatter Lobe, and then possible chatter and corresponding adjustment of cutting conditions will be provided.

5-axis Machining Feature: (Patent: M437221)

Different from general BC-type, the U-600 is designed as AC type for extensive machining capacity that allows workpiece diameter larger than axis travel. Additionally, such configuration is in favor for view and access.

Wide Operation Area (Patent: M436520)

The operation area is defined with 2 sliding doors with wide open space. The user is allowed to operate from 2 directions for easy operation and clear monitoring on the workpiece. This design is also in favor for loading/unloading, featuring excellent access.

One-piece Base-Column

The base and column are structured as one-piece casting, which eliminates possible tolerance of the jointing interfaces. The tool magazine is directed mounted onto this one-piece structure so that torque twist is decreased and stability increased. Box-structure casting and optimal span realize exceptional rigidity and stability. Large hole on the back offers convenience for assembling and maintenance.

3 Overlapped Axes with 2 Rotating Axes

Axes of linear movement and rotation are separated so that during 5-axis machining, curve tolerance or error can be controlled and adjusted rather easily.

FEELER U800-5AX

High Speed Precision Machining, Unmatched Performance

The Feeler 5-axis machining center is designed specifically for high precision machining and creating extra fine finish. Its gantry type structure together with U-shaped base and column brings the structural stability to a new level. The swiveling rotary table diameter is 800mm and capable of resisting heavy loads. This machine is equipped with a 12,000rpm direct-drive spindle that fully satisfies customers’ expectations in high speed and high efficiency machining.

Gantry Type Structure

Designed with a gantry type structure, the Feeler USOO-SAX 5-axis machining center has the feature of spacious machining space, allowing large workpiece to be loaded and unloaded with ease. It is also convenient for operator to check the current machining condition at any time.

U-shaped Construction of Base and Column

• The advanced U-Shape structure significantly increases structural rigidity and machining accuracy.

• X.Y.Z-axis rapid traverse rate reach 48m/min.

• Suitable for equipping with a large diameter of rotary table.

Three Axes Overlap and Separated from Two Rotary Axes

• This design avoids a distance between the machining point and the intersection point of two rotating axes.

• Easy to compensate for the errors of radius on rotating axes and movement on three linear axes to ensure the machine’s stability and accuracy.

Separated Design for Three Axes Moving Area and Machining Area

• This design feature not only makes chip removal more convenient, but also enables better chip-prevention capability of the machine.

QUASER UX500

UX500

This single unit machine features high rigidity, accuracy, and efficiency and offers a high ease of operation with a relatively compact footprint.

The Symmetrical design ensures the rigidity of the machine tool, which results in better damping performance and lower thermal displacement.

The modular design allows for expandable multi-pallet configurations.

Applications

- Automobile: control arm, bracket, engine block.

- Aerospace: blisk, impeller, turbine blade.

- Medical: titanium artificial knee joint, dental part.

- Mold & die: tire mold & die in tool steel, plastic mold.

QUASER UX500APC

UX500APC

UX500APC is a highly versatile five-axis VMC with automatic pallet changer.

The Symmetrical design ensures the rigidity of the machine tool, which results in better damping performance and lower thermal displacement.

The dual work zone design can reduce the machine down time due to the workpiece load / unload to increase the utilization rate.

The UX500APC is modular and expandable: End users can expand the number of work pallets and tools according to the machining demand.

Applications

Machining of parts with more complex curved surfaces.

- Automated automotive industry and high-precision complex workpiece requirements.

- High-end processing of aerospace components.

- Automobile: control arm, bracket.

- Medical: titanium artificial knee joint, dental part.

- Mold & die: tire mold & die in tool steel, plastic mold.

QUASER UX630

UX630

The UX630 with a B-axis +/- 120 degrees, X-axis 900mm working stroke can meet the high demand of the diversity and the flexibility of five-axis machining.

Centralized lubrication and air pressure plate are well located to make machine maintenance easy.

The chips are discharged directly through the high-efficiency chip conveyor under the machine table, and the chips are discharged quickly, in large quantities, saving machine maintenance time.

Applications

- Automobile: control arm, bracket, engine block.

- Aerospace: blisk, impeller, turbine blade.

- Medical: titanium artificial knee joint, dental part.

- Mold & die: tire mold & die in tool steel, plastic mold.

QUASER UX630APC

UX630APC

The UX630APC table allows for heavy loading: up to 500kg with maximum swing of 630mm and height 480mm to meet the demands of medium size work piece for 5 Axis simultaneous machining.

Compact design with excellent accessibility allows the operator to easily reach the work piece and spindle to adjust tools and conduct workpiece measurement. The automatic pallet changer mechanism (APC) minimizes the machine’s standstill time to enhance machine productivity.

Applications

- Automobile: control arm, bracket, engine block.

- Aerospace: blisk, impeller, turbine blade.

- Medical: titanium artificial knee joint, dental part.

- Mold & die: tire mold & die in tool steel, plastic mold.

QUASER UX600C

UX600C

The double column structure design emphasizes excellent performance in terms of accuracy, mechanical rigidity, and machining stability.

Stable and compression-resistant design to ensure the spindle torsion, cutting ability, and worktable load.

Due to our outstanding craftsmanship, our machine has better cutting performance and better machining accuracy than most competitors’ in its class.

Applications

- Automobile: control arm, bracket, engine block.

- Aerospace: blisk, impeller, turbine blade.

- Medical: titanium artificial knee joint, dental part.

- Mold & die: tire mold & die in tool steel, plastic mold.

QUASER UX600P

UX600P

The double column structure design emphasizes excellent performance in terms of accuracy, mechanical rigidity, and machining stability.

Stable and compression-resistant design to ensure the spindle torsion, cutting ability, and worktable load.

Applications

- Automobile: control arm, bracket, engine block.

- Aerospace: blisk, impeller, turbine blade.

- Medical: titanium artificial knee joint, dental part.

- Mold & die: tire mold & die in tool steel, plastic mold.

QUASER UX800

UX800

Quaser Group provides technology and application expertise to enable the best manufacturing performance

FEELER FMH Series

FEELER HORIZONTAL MACHINING CENTERS

No matter whether it is precision parts machining or general mold machining, the new generation FMH Series horizontal machining center from FEELER will provide you with the outstanding performance that you’ve came to expect. The FMH Series is carefully designed and engineered for the utmost accuracy.

EXCELLENT FOR DIVERSIFIED INDUSTRIES

• Precision(profiled) Parts Machining

• General Mold Machining

• Automotive and Motorcycle Part Machining

• 3C Industries

• Aerospace Part Machining

• Semi-conductor Industry

• FMC&FMS Unmanned Production Lines

The FEELER FMH Series Horizontal Machining Centers are designed and engineered with efficiency, stability and heavy duty in mind. It is a machining center excellent for precision mold machining and heavy parts machining. The brand new design concept of FMH series horizontal machining centers are dedicated to machine both mass production parts and general molds with high accuracy. The outstanding performance of FMH series machines from FEELER brings you the utmost cutting efficiency as well as maximum profitability.

SPECIAL HIGH/LOW LINEAR WAYS CONSTRUCTION

• The T-shaped base is an integrated 3-layer box-type construction combined with rib reinforcement to maximize the rigidity and stability of the machine.

• The housing-type double-wall column is ruggedly constructed to assure high accuracy during heavyduty machining.

• The base is specially designed with high/low linear ways, which effectively shorten force loading lines while greatly increasing machining stability.

THREE AXES LINEAR WAYS HANDLES HEAVY LOADS

• Three axes are fully equipped with linear guide ways, combined with double rows support at both sides, for increased loading capacity, high rigidity and high accuracy. No further maintenance is required for long term operations.

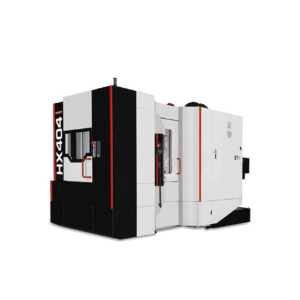

QUASER HX404

HX404

The large Z axis span of HX404 allows the machine to deal with high work pieces and to strengthen machining stability with high rigidity.

The HX404 utilizes W-shaped Z axis telescopic covers to deal with stacked chips, combined with the integrated coolant wash, internal chip augers and external lift up chip conveyor, enhances the management of chip disposal.

In addition, the easy operation and ergonomic accessibility for HX404 allow s operator easily to reach machining work piece, spindle and load/unload station. The HX404 also features small floor space, which makes the best space utilization for clients.

Applications

HX404 is widely applied to high standard industries, such as automobile, aerospace, mechanical parts…and so forth. More importantly, in response to automation, it is able to combine with multi-pallet and larger tool magazine to increase productivity efficiency and lower labor cost to make the best resources allocation.

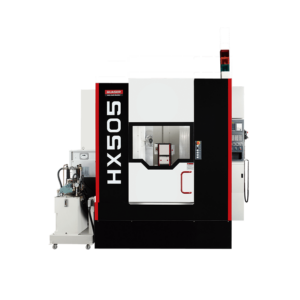

QUASER HX504 / HX505

HX504 / HX505

The HX series horizontal machining centers are designed for unsurpassed productivity and ultimate precision due to minimized non-cutting time and stable machine structure.

These compact high speed machining centers provide our customers with the best flexibility in parts production.

Advanced factory automation equipment is available for higher productivity.

Applications

Automobile, aerospace, energy parts, shipbuilding, construction machinery, shipbuilding, heavy industry…Industries.

QUASER HX635

HX635

The one-piece T shape base on the HX635/ 805 machines are better than competitive machine bases that offer a 3 piece design. They offer better overhang and lower deformation to make the machine’s features not only durable but also outstanding during the machining.

The moving column design provides the best accuracy in both dynamic and static condition.

A One-piece design of table accomplishes the best rigidity.

Applications

Energy parts, shipbuilding, construction machinery, heavy industry…Industries.

QUASER HX805

HX805

The one-piece T shape base on the HX635/ 805 machines are better than competitive machine bases that offer a 3 piece design. They offer better overhang and lower deformation to make the machine’s features not only durable but also outstanding during the machining.

The moving column design provides the best accuracy in both dynamic and static condition.

A One-piece design of table accomplishes the best rigidity.

Applications

Energy parts, shipbuilding, construction machinery, heavy industry…Industries.

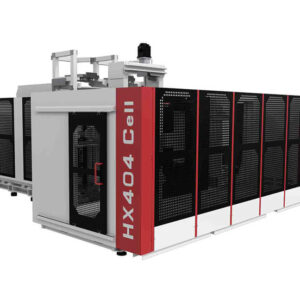

QUASER HX404 Cell

HX404 Cell

FMC series is an automated solution to maximize productivity. Simple installation and ease of maintenance makes it convenient for users to operate and maintain.

Automation equipment available for one single machine to multiple production lines.

Applications

Automobile, aerospace, construction machinery.…industries.

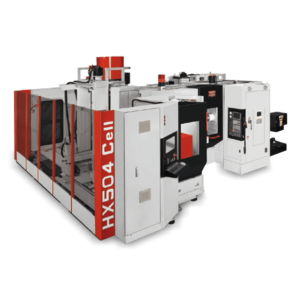

QUASER HX504 Cell / HX505 Cell

HX504 Cell / HX505 Cell

FMC series is an automated solution to maximize productivity. Simple installation and ease of maintenance makes it convenient for users to operate and maintain.

Automation equipment available for one single machine to multiple production lines.

Applications

Automobile, aerospace, construction machinery.…industries.

FFG DMC DL 6G

DL 6G

Travel (X/Z)(mm)(inch) 420 x 250 16.54 x 9.84

Guideway Type L.M Guide

Spindle speed(rpm) 6,000

Max. No. of Tool(pcs) 6

FFG DMC DL 8G

DL 8G

Travel (X/Z)(mm)(inch) 420 x 250 16.54 x 9.84

Guideway Type L.M Guide

Spindle speed(rpm) 4,500

Max. No. of Tool(pcs) 6

FFG DMC DL 6GB

DL 6GB

Travel (X/Z)(mm)(inch) 400 x 250 15.75 x 9.84

Guideway Type BOX Way

Spindle speed(rpm) 6,000

Max. No. of Tool(pcs) 6

FFG DMC DL 8GB

DL 8GB

Travel (X/Z)(mm)(inch) 300 x 235 15.75 x 9.84

Guideway Type BOX Way

Spindle speed(rpm) 4,500

Max. No. of Tool(pcs) 6

FFG DMC DL 3G

DL 3G

Travel (X/Z)(mm)(inch) 200 x 180 (7.87″ x 7.09″)

Guideway Type Dove-tail

Spindle speed(rpm) 6,000 rpm

Max. No. of Tool(pcs) 5 pcs

FFG DMC DL 6G

DL 6GF

Travel (X/Z)(mm)(inch) 200 x 200 (7.87″ x 7.87″)

Guideway Type Dove-tail

Spindle speed(rpm) 6,000 rpm

Max. No. of Tool(pcs) 3 pcs