QUASER HX635

HX635

The one-piece T shape base on the HX635/ 805 machines are better than competitive machine bases that offer a 3 piece design. They offer better overhang and lower deformation to make the machine’s features not only durable but also outstanding during the machining.

The moving column design provides the best accuracy in both dynamic and static condition.

A One-piece design of table accomplishes the best rigidity.

Applications

Energy parts, shipbuilding, construction machinery, heavy industry…Industries.

QUASER HX805

HX805

The one-piece T shape base on the HX635/ 805 machines are better than competitive machine bases that offer a 3 piece design. They offer better overhang and lower deformation to make the machine’s features not only durable but also outstanding during the machining.

The moving column design provides the best accuracy in both dynamic and static condition.

A One-piece design of table accomplishes the best rigidity.

Applications

Energy parts, shipbuilding, construction machinery, heavy industry…Industries.

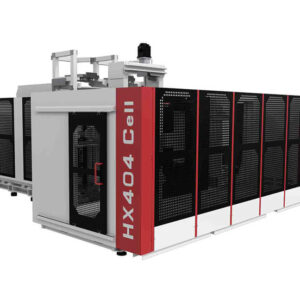

QUASER HX404 Cell

HX404 Cell

FMC series is an automated solution to maximize productivity. Simple installation and ease of maintenance makes it convenient for users to operate and maintain.

Automation equipment available for one single machine to multiple production lines.

Applications

Automobile, aerospace, construction machinery.…industries.

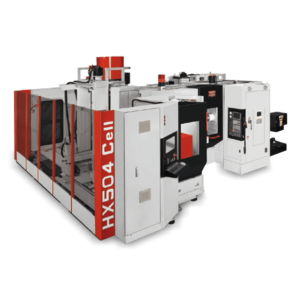

QUASER HX504 Cell / HX505 Cell

HX504 Cell / HX505 Cell

FMC series is an automated solution to maximize productivity. Simple installation and ease of maintenance makes it convenient for users to operate and maintain.

Automation equipment available for one single machine to multiple production lines.

Applications

Automobile, aerospace, construction machinery.…industries.

FFG DMC DL 6G

DL 6G

Travel (X/Z)(mm)(inch) 420 x 250 16.54 x 9.84

Guideway Type L.M Guide

Spindle speed(rpm) 6,000

Max. No. of Tool(pcs) 6

FFG DMC DL 8G

DL 8G

Travel (X/Z)(mm)(inch) 420 x 250 16.54 x 9.84

Guideway Type L.M Guide

Spindle speed(rpm) 4,500

Max. No. of Tool(pcs) 6

FFG DMC DL 6GB

DL 6GB

Travel (X/Z)(mm)(inch) 400 x 250 15.75 x 9.84

Guideway Type BOX Way

Spindle speed(rpm) 6,000

Max. No. of Tool(pcs) 6

FFG DMC DL 8GB

DL 8GB

Travel (X/Z)(mm)(inch) 300 x 235 15.75 x 9.84

Guideway Type BOX Way

Spindle speed(rpm) 4,500

Max. No. of Tool(pcs) 6

FFG DMC DL 3G

DL 3G

Travel (X/Z)(mm)(inch) 200 x 180 (7.87″ x 7.09″)

Guideway Type Dove-tail

Spindle speed(rpm) 6,000 rpm

Max. No. of Tool(pcs) 5 pcs

FFG DMC DL 6G

DL 6GF

Travel (X/Z)(mm)(inch) 200 x 200 (7.87″ x 7.87″)

Guideway Type Dove-tail

Spindle speed(rpm) 6,000 rpm

Max. No. of Tool(pcs) 3 pcs

FFG DMC DL 5GH

DL 5GH

Travel (X/Z)(mm)(inch) 300 x 235 (11.81″ x 9.25″)

Guideway Type Dove-tail

Spindle speed(rpm) 6,000 rpm

Max. No. of Tool(pcs) 5 pcs

FFG DMC Q5-2S

Q5-2S

Travel (X/Z)(mm)(inch) 200 x 235 (11.81″ x 9.25″)

Guideway Type Dove-tail

Spindle speed(rpm) 6,000 rpm

Max. No. of Tool(pcs) 5 pcs

FFG DMC DL 6T

DL 6T

Travel (X/Z)(mm)(inch) 160 x 350 (6.30″ x 13.78″)

Guideway Type LM Guide

Spindle speed(rpm) 6,000 rpm

Max. No. of Tool(pcs) 10 (6+6)

FFG DMC DL 8TH

DL 8TH

Travel (X/Z)(mm)(inch) 160 x 520 (6.30″ x 20.47″)

Guideway Type LM Guide

Spindle speed(rpm) 4,500 rpm

Max. No. of Tool(pcs) 10

FFG DMC DL 10TMH

DL 10TMH

Travel (X/Z)(mm)(inch) 160 x 380 (6.30″ x 14.96″)

Guideway Type LM Guide

Spindle speed(rpm) 3,500 rpm

Max. No. of Tool(pcs) 12

FFG DMC DL 24TTGA

Main Specification

Axis Travel (X/Z)(mm)(inch) 190 x 200 (7.48″ x 7.87″)

Standard Chuck 8″

Max Turning Dia.(mm)(inch) 150 (5.91″)

Max Turning Length (mm)(inch) 150 (5.91″)

Loader Specification

Working Size (mm) 0D Ø250x150L / ID Ø250x100L

Working Size (inch) 0D Ø9.84″x59.06L / ID Ø9.84″x3.94″L

A/B/C-axis Speed (m/min)(ipm) 127/76/52 (5000/2992/2047)

Max. Handling Weight(kgf)(lbs) 8+8(17.64+16.64)

FFG DMC DL 24TTGB

Main Specification

Axis Travel (X/Z)(mm)(inch) 190 x 200 (7.48″ x 7.87″)

Standard Chuck 10″

Max Turning Dia.(mm)(inch) 250 (9.84″)

Max Turning Length (mm)(inch) 150 (5.91″)

Loader Specification

Working Size (mm) 0D Ø250x150L / ID Ø250x100L

Working Size (inch) 0D Ø9.84″x5.91L / ID Ø9.84″x3.94″L

A/B/C-axis Speed (m/min)(ipm) 127/76/52 (5000/2992/2047)

Max. Handling Weight(kgf)(lbs) 8+8(17.64+17.64)

FFG DMC DL 21MA

DL 21MA

Travel (X/Z) (mm) (inch) 200 x 410 mm (7.87″ x 16.14″)

Guideway Type Roller Guide Way

Spindle speed (rpm) 4,000 rpm

Max. No. of Tool (pcs) 12 pcs

FFG DMC DL 21LMA

DL 21LMA

Travel (X/Z) (mm) (inch) 200 x 550 mm (7.87″ x 21.65″)

Guideway Type Roller Guide Way

Spindle speed (rpm) 4,000 rpm

Max. No. of Tool (pcs) 12 pcs

FFG DMC DL 22LMA

DL 22LMA

Travel (X/Z) (mm) (inch) 200 x 550 mm (7.87″ x 21.65″)

Guideway Type Roller Guide Way

Spindle speed (rpm) 4,000 rpm

Max. No. of Tool (pcs) 12 pcs

FFG DMC DL 22LMB

DL 22LMB

Travel (X/Z) (mm) (inch) 200 x 550 mm (7.87″ x 21.65″)

Guideway Type Roller Guide Way

Spindle speed (rpm) 3,500 rpm

Max. No. of Tool (pcs) 12 pcs

FFG DMC DL 25

DL 25

Travel (X/Z) (mm) (inch) 230 x 1,130 (9.06″ x 44.49″)

Guideway Type BOX Way

Spindle speed (rpm) 3,500

Max. No. of Tool (pcs) 12

FFG DMC DL 40

DL 40

Travel (X/Z) (mm) (inch) 305 x 1,305 (12.01″ x 51.38″)

Guideway Type BOX Way

Spindle speed (rpm) 2,000

Max. No. of Tool (pcs) 10

FFG DMC DL 45

DL 45

Travel (X/Z) (mm) (inch) 350 x 4,530 (13.78″ x 60.24″)

Guideway Type BOX Way

Spindle speed (rpm) 2,000

Max. No. of Tool (pcs) 12

FFG DMC DL 55

DL 55

Travel (X/Z) (mm) (inch) 350 x 1,530 (13.78″ x 60.24″)

Guideway Type BOX Way

Spindle speed (rpm) 1,700

Max. No. of Tool (pcs) 12

FFG DMC DL 60L

DL 60L

Travel (X/Z) (mm) (inch) 470 x 3,270 (18.50″ x 128.74″)

Guideway Type BOX Way

Spindle speed (rpm) 1,400

Max. No. of Tool (pcs) 12

FFG DMC DL 22LMS

DL 22LMS

Travel (X/Z/B/Y) (mm) (inch) 470 x 3,270 (7.48″ x 21.65″ x 22.83″ x -)

Guideway Type (X/Z/B/Y) BOX Way

Main spindle speed (rpm) 1,400

Number of Tool (pcs) 12

FFG DMC DL 25SY

DL 22SY

Travel (X/Z/B/Y) (mm) (inch) 220 x 1,050 (8.66″ x 41.34″ x 37″ x ±2.17)

Guideway Type (X/Z/B/Y) BOX Way

Main spindle speed (rpm) 3,500

Number of Tool (pcs) 12

TRAK TC820SI

Hardened Box Ways on a Solid Casting provide increased rigidity, better damping, and less vibration for all purpose heavy duty cutting.

12-Station Bolt-On Turret for 0.75″ tooling with hydraulic locking system provides a reliable, precise interface between the machine, the tool and the work piece.

Coolant Through Turret efficiently dissipates chips and heat during machining. This greatly enhances cutting performance, accuracy, surface finish and tool life.

Manual Tailstock with Hydraulic Quill provides additional support for longer workpieces. Quill stroke of 4.13″ with MT4 taper.

4,000 RPM Spindle with 2.56″ Bar Capacity provides high axial thrust and generates minimal heat. It uses four P4 class angular bearings for optimal support and rigidity.

Tool Setting Arm and Probe with user-friendly interface for fast and reliable tool setup.

Direct Drive on X and Z Axes provide a rigid connection between the motor and the ballscrew for optimum servo control. This enhances accuracy and eliminates backlash.

Automatic Lubrication controlled by the CNC system monitors and distributes oil to the box ways and ballscrews to ensure all critical components are always lubricated with the correct amount of oil.

Standard Coolant System features a 20-gallon tank and pump providing coolant through tool @ 30 psi. High-pressure coolant option also available.

SIMOTICS M-1PH8 Asynchronous Induction Spindle Motor with 14.75 HP continuous — capable of handling extreme duty cycles and short rise times.

Chip Conveyor features an internal collection and side discharge system with a high rate of material removal. Chip cart is optional.

High Performance Servo Motors with excellent positioning accuracy.

Other Standard Features:

- Small footprint and generous 8.66″ maximum turned diameter and 20″ maximum turned length.

- Heavy Machine Tool Construction provides mass for rigidity and heavy cuts.

- Solid Casting for vibration absorption and rigidity.

- Precision Ground Ballscrews

- Guarding on All Axes to protect the castings, ballscrews and drivetrain systems.

- 7.88″ Hydraulic 3 Jaw Chuck for A2-6 spindle nose

- 787 IPM Feedrate on Z-Axis and 590 IPM Feedrate on X-Axis with aggressive acceleration and jerk control for ultra-fast positioning and reduced cycle times.

- Absolute Position Encoders to eliminate homing and enhance precision.

- Fine Chip Strainer has a metal screen with 1.7 mm openings to prevent large chips from clogging the coolant pumps.

- Large Single Front Door with large viewing window for easy access and integration with automation.

VISION WIDE SM Series

The structural analysis and optimization of the SM machine model stabilizes the structure of the fuselage and provides the best high dynamic rigidity when the machine moves at high speed.

High-precision positioning and emphasis on positioning accuracy provide the best choice for precision machining of auto parts, small car molds, mold bases, mechanical hardware parts and so on.

- Large table clamping area

- Optimized positioning accuracy

- Y axis increases machining stroke

- 15m / min high-speed cutting feed

- Structural design of machine tools for high-torque high-speed cutting applications

- Torque output of full tooth spindle 1,163Nm (15 / 18.5kW)