YCM DCV3018A-5AX

- One-piece Column

- One-piece Base

- Ultimate rigidity and proportion of the headstock

- Internal double A type ribbed bed design through FEM analysis offers full support for table.

- 1,800 mm distance between columns increases the stability of machine

- Roller type linear guideways on X / Y / Z-axis.

- Y axis linear guideways design with large span with horizontal and vertical directions which can take the saddle weight and machining force.

- Direct driven motors on Y / Z-axis reduce backlash and ensure perfect axial accuracy.

- X-axis is gearbox driven.

- The work table is precisely ground before assembled to ensure DCV series excellent machining results.

- 10 tons maximum table machining loading.

- DD motor drive, no backlash.

- B/C axis rotary speed 100 rev/min.

- C-axis includes three roller bearings to increase rigidity and accuracy.

- B-axis high rigidity and high accuracy cross roller bearing.

- Heidenhain accuracy encoder included as standard.

- Pneumatic positioning clamping equipment.

- Over travel protection design.

- B-axis anti-drop function at power outage.

- Deliver maximum spindle speed of up to 18,000 rpm driven by 56/70kW motor

YCM DCV3021B

- Turcite-B design on Z-axis strengthens rigidity and damping capacity reducing overhang and vibration problems

- Extra wide column base with boots design prevents the headstock from leaning forward

- Internal ribs structure design through FEM analysis delivers high rigidity and stability

- Direct drive gearbox design on X-axis offers smooth axial response, high torque, and low backlash

- X-axis is equipped with 3 roller type guideways and numerous slider blocks for great load capacity of 12 slider blocks

- 3 roller type guideways on Y-axis strongly support the headstock and saddle

- With Hi-lo Gear Transmission

- 4,500rpm spindle speed is standard with 2-step gear transmission.

- The spindle incorporates roller type spindle bearings for extremely high cutting rigidity.

- The 2-step gear transmission provides 88.87kgf-m torque output at 241rpm ideal for machining hard material.

YCM DCV3025B

- Turcite-B design on Z-axis strengthens rigidity and damping capacity reducing overhang and vibration problems

- Extra wide column base with boots design prevents the headstock from leaning forward

- Internal ribs structure design through FEM analysis delivers high rigidity and stability

- Direct drive gearbox design on X-axis offers smooth axial response, high torque, and low backlash

- X-axis is equipped with 3 roller type guideways and numerous slider blocks for great load capacity of 12 slider blocks

- 3 roller type guideways on Y-axis strongly support the headstock and saddle

- With Hi-lo Gear Transmission

- 4,500rpm spindle speed is standard with 2-step gear transmission.

- The spindle incorporates roller type spindle bearings for extremely high cutting rigidity.

- The 2-step gear transmission provides 88.87kgf-m torque output at 241rpm ideal for machining hard material.

YCM DCV4016B

- One-piece Column

- One-piece Base

- Rigid proportion of the headstock

- With Hi-lo Gear Transmission

- 4,500rpm spindle speed is standard with 2-step gear transmission.

- The spindle incorporates roller type spindle bearings for extremely high cutting rigidity.

- The 2-step gear transmission provides 88.87kgf-m torque output at 241rpm ideal for machining hard material.

- X-axis is directly driven by gearbox offering smooth axial response and high torque

- Roller type guideways on X/Y axis

- Y-axis is supported by 3 roller type guideways and 6 slider blocks to offer ultimate cutting rigidity

- Horizontal and vertical support of the headstock

- Hardened and ground box guideway on Z-axis enlarges the contact interface for high machining stability

YCM DCV4018A-5AX

- One-piece Column

- One-piece Base

- Ultimate rigidity and proportion of the headstock

- Internal double A type ribbed bed design through FEM analysis offers full support for table.

- 1,800 mm distance between columns increases the stability of machine

- Roller type linear guideways on X / Y / Z-axis.

- Y axis linear guideways design with large span with horizontal and vertical directions which can take the saddle weight and machining force.

- Direct driven motors on Y / Z-axis reduce backlash and ensure perfect axial accuracy.

- X-axis is gearbox driven.

- The work table is precisely ground before assembled to ensure DCV series excellent machining results.

- 12 tons maximum table machining loading.

- DD motor drive, no backlash.

- B/C axis rotary speed 100 rev/min.

- C-axis includes three roller bearings to increase rigidity and accuracy.

- B-axis high rigidity and high accuracy cross roller bearing.

- Heidenhain accuracy encoder included as standard.

- Pneumatic positioning clamping equipment.

- Over travel protection design.

- B-axis anti-drop function at power outage.

- Deliver maximum spindle speed of up to 18,000 rpm driven by 56/70kW motor

YCM DCV4021B

- Turcite-B design on Z-axis strengthens rigidity and damping capacity reducing overhang and vibration problems

- Extra wide column base with boots design prevents the headstock from leaning forward

- Internal ribs structure design through FEM analysis delivers high rigidity and stability

- Direct drive gearbox design on X-axis offers smooth axial response, high torque, and low backlash

- X-axis is equipped with 3 roller type guideways and numerous slider blocks for great load capacity of 15 slider blocks

- 3 roller type guideways on Y-axis strongly support the headstock and saddle

- With Hi-lo Gear Transmission

- 4,500rpm spindle speed is standard with 2-step gear transmission.

- The spindle incorporates roller type spindle bearings for extremely high cutting rigidity.

- The 2-step gear transmission provides 88.87kgf-m torque output at 241rpm ideal for machining hard material.

YCM DCV4025B

- Turcite-B design on Z-axis strengthens rigidity and damping capacity reducing overhang and vibration problems

- Extra wide column base with boots design prevents the headstock from leaning forward

- Internal ribs structure design through FEM analysis delivers high rigidity and stability

- Direct drive gearbox design on X-axis offers smooth axial response, high torque, and low backlash

- X-axis is equipped with 3 roller type guideways and numerous slider blocks for great load capacity of 15 slider blocks

- 3 roller type guideways on Y-axis strongly support the headstock and saddle

- With Hi-lo Gear Transmission

- 4,500rpm spindle speed is standard with 2-step gear transmission.

- The spindle incorporates roller type spindle bearings for extremely high cutting rigidity.

- The 2-step gear transmission provides 88.87kgf-m torque output at 241rpm ideal for machining hard material.

YCM DCV4030B-5AF

- High rigidity symmetrical fork type structure design minimizes heat deformation during heavy cutting applications.

- The main structure is made of superior nodular graphite cast iron.

- High dynamic universal milling head, built-in motorized spindle with HSK-A100 taper offers max. spindle speed 10,000 rpm.

- Coolant through spindle system: 20 bar (opt.)

- Superb spindle coolant system.

- Direct drive motor design delivers high torque, low backlash and perfect clamping capacity.

- HEIDENHAIN encoder enhances the cutting accuracy.

- Disc type hydraulic clamping device.

- Rotary joint design prevents the damage on the hydraulic tubes caused during rotation.

- Double direction roller bearings for perfect cutting rigidity.

- Massive MEEHANITE® casting through FEM analysis offers exceptional damping capacity.

- Direct drive gearbox design on X/Y/Z axis offers smooth axial response, high torque, and low backlash.

- Extra wide column base with boots design.

- Equipped with roller type guideways and numerous slider blocks for great load capacity and cutting rigidity.

- 10,000 rpm IDD spindle is optional to be equipped with DCV series. Driven by 46 kW dual step AC digital spindle motor, the spindle is able to reach max. 36.04 kgf-m torque output at 500 rpm.

- Unique IDD design offers low spindle vibration and optimal heat isolation that results in excellent accuracy after longterm operation.

YCM DCV4030B-5AX

- High rigidity symmetrical fork type structure design minimizes heat deformation during heavy cutting applications.

- The main structure is made of superior nodular graphite cast iron.

- High dynamic universal milling head, built-in motorized spindle with HSK-A100 taper offers max. spindle speed 10,000 rpm.

- Coolant through spindle system: 20 bar (opt.)

- Superb spindle coolant system.

- Direct drive motor design delivers high torque, low backlash and perfect clamping capacity.

- HEIDENHAIN encoder enhances the cutting accuracy.

- Disc type hydraulic clamping device.

- Rotary joint design prevents the damage on the hydraulic tubes caused during rotation.

- Double direction roller bearings for perfect cutting rigidity.

- Massive MEEHANITE® casting through FEM analysis offers exceptional damping capacity.

- Direct drive gearbox design on X/Y/Z axis offers smooth axial response, high torque, and low backlash.

- Extra wide column base with boots design.

- Equipped with roller type guideways and numerous slider blocks for great load capacity and cutting rigidity.

- 5-axis simultaneous control by HEIDENHAIN TNC640 increases efficiency, tool life, and cutting accuracy.

- Program memory hard disk with 21 GB.

- Tool center point management [TCPM]

- Dynamic collision monitoring [DCM]

- DXF converter (opt.)

- 10,000rpm IDD spindle is optional to be equipped with DCV series. Driven by 46kW dual step AC digital spindle motor, the spindle is able to reach max. 36.04kgf-m torque output at 500rpm.

- Unique IDD design offers low spindle vibration and optimal heat isolation that results in excellent accuracy after longterm operation.

YCM DCV4035B

- Turcite-B design on Z-axis strengthens rigidity and damping capacity reducing overhang and vibration problems

- Extra wide column base with boots design prevents the headstock from leaning forward

- Internal ribs structure design through FEM analysis delivers high rigidity and stability

- Direct drive gearbox design on X-axis offers smooth axial response, high torque, and low backlash

- X-axis is equipped with 3 roller type guideways and numerous slider blocks for great load capacity of 15 slider blocks

- 3 roller type guideways on Y-axis strongly support the headstock and saddle

- 4,500rpm spindle speed is standard with 2-step gear transmission.

- The spindle incorporates roller type spindle bearings for extremely high cutting rigidity.

- The 2-step gear transmission provides 88.87kgf-m torque output at 241rpm ideal for machining hard material.

YCM DCV5021B

- Turcite-B design on Z-axis strengthens rigidity and damping capacity reducing overhang and vibration problems.

- Extra wide column base with boots design prevents the headstock from leaning forward.

- Internal ribs structure design through FEM analysis delivers high rigidity and stability.

- In the picture, A and B are designed by competitors and YCM respectively.

- Direct drive gearbox design on X-axis offers smooth axial response, high torque, and low backlash.

- X-axis is equipped with 3 roller type guideways and numerous slider blocks for great load capacity of 18 slider blocks.

- 3 roller type guideways on Y-axis strongly support the headstock and saddle.

- 4,500 rpm spindle speed is standard with 2-step gear transmission.

- The spindle incorporates roller type spindle bearings for extremely high cutting rigidity.

- The 2-step gear transmission provides 88.87 kgf-m torque output at 241 rpm ideal for machining hard material.

YCM DCV5025B

- Turcite-B design on Z-axis strengthens rigidity and damping capacity reducing overhang and vibration problems.

- Extra wide column base with boots design prevents the headstock from leaning forward.

- Internal ribs structure design through FEM analysis delivers high rigidity and stability.

- In the picture, A and B are designed by competitors and YCM respectively.

- Direct drive gearbox design on X-axis offers smooth axial response, high torque, and low backlash.

- X-axis is equipped with 3 roller type guideways and numerous slider blocks for great load capacity of 18 slider blocks.

- 3 roller type guideways on Y-axis strongly support the headstock and saddle.

- 4,500 rpm spindle speed is standard with 2-step gear transmission.

- The spindle incorporates roller type spindle bearings for extremely high cutting rigidity.

- The 2-step gear transmission provides 88.87 kgf-m torque output at 241 rpm ideal for machining hard material.

YCM DCV5030B-5AX

- High rigidity symmetrical fork type structure design minimizes heat deformation during heavy cutting applications.

- The main structure is made of superior nodular graphite cast iron.

- High dynamic universal milling head, built-in motorized spindle with HSK-A100 taper offers max. spindle speed 10,000 rpm.

- Coolant through spindle system: 20 bar (opt.)

- Superb spindle coolant system.

- Direct drive motor design delivers high torque, low backlash and perfect clamping capacity.

- HEIDENHAIN encoder enhances the cutting accuracy.

- Disc type hydraulic clamping device.

- Rotary joint design prevents the damage on the hydraulic tubes caused during rotation.

- Double direction roller bearings for perfect cutting rigidity.

- Massive MEEHANITE® casting through FEM analysis offers exceptional damping capacity.

- Direct drive gearbox design on X/Y/Z axis offers smooth axial response, high torque, and low backlash.

- Extra wide column base with boots design.

- Equipped with roller type guideways and numerous slider blocks for great load capacity and cutting rigidity.

- 5-axis simultaneous control by HEIDENHAIN TNC640 increases efficiency, tool life, and cutting accuracy.

- Program memory hard disk with 21 GB.

- Tool center point management [TCPM]

- Dynamic collision monitoring [DCM]

- DXF converter (opt.)

- 10,000 rpm IDD spindle is optional to be equipped with DCV series. Driven by 46 kW dual step AC digital spindle motor, the spindle is able to reach max. 36.04 kgf-m torque output at 500 rpm.

- Unique IDD design offers low spindle vibration and optimal heat isolation that results in excellent accuracy after longterm operation.

YCM DCV6030B-5AX

- High rigidity symmetrical fork type structure design minimizes heat deformation during heavy cutting applications.

- The main structure is made of superior nodular graphite cast iron.

- High dynamic universal milling head, built-in motorized spindle with HSK-A100 taper offers max. spindle speed 10,000 rpm.

- Coolant through spindle system: 20 bar (opt.)

- Superb spindle coolant system.

- Direct drive motor design delivers high torque, low backlash and perfect clamping capacity.

- HEIDENHAIN encoder enhances the cutting accuracy.

- Disc type hydraulic clamping device.

- Rotary joint design prevents the damage on the hydraulic tubes caused during rotation.

- Double direction roller bearings for perfect cutting rigidity.

- Massive MEEHANITE® casting through FEM analysis offers exceptional damping capacity.

- Direct drive gearbox design on X/Y/Z axis offers smooth axial response, high torque, and low backlash.

- Extra wide column base with boots design.

- Equipped with roller type guideways and numerous slider blocks for great load capacity and cutting rigidity.

- 5-axis simultaneous control by HEIDENHAIN TNC640 increases efficiency, tool life, and cutting accuracy.

- Program memory hard disk with 21 GB.

- Tool center point management [TCPM]

- Dynamic collision monitoring [DCM]

- DXF converter (opt.)

- 10,000 rpm IDD spindle is optional to be equipped with DCV series. Driven by 46 kW dual step AC digital spindle motor, the spindle is able to reach max. 36.04 kgf-m torque output at 500 rpm.

- Unique IDD design offers low spindle vibration and optimal heat isolation that results in excellent accuracy after longterm operation.

YCM DCV6035B

- Turcite-B design on Z-axis strengthens rigidity and damping capacity reducing overhang and vibration problems.

- Extra wide column base with boots design prevents the headstock from leaning forward.

- Internal ribs structure design through FEM analysis delivers high rigidity and stability.

- In the picture, A and B are designed by competitors and YCM respectively.

- Direct drive gearbox design on X-axis offers smooth axial response, high torque, and low backlash.

- X-axis is equipped with 3 roller type guideways and numerous slider blocks for great load capacity of 21 slider blocks.

- 3 roller type guideways on Y-axis strongly support the headstock and saddle.

- 4,500 rpm spindle speed is standard with 2-step gear transmission.

- The spindle incorporates roller type spindle bearings for extremely high cutting rigidity.

- The 2-step gear transmission provides 88.87 kgf-m torque output at 241 rpm ideal for machining hard material.

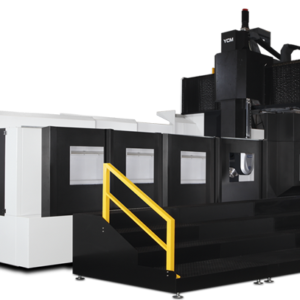

YCM DCV2012B

- One-piece Column

- One-piece Base

- Roller type guideways on X/Y axis

- Horizontal and vertical support of the headstock

- Direct drive motors on 3 axes reduce backlash and ensure perfect axial accuracy

- Three axes adopt highly responsive servo motor, configuring ball screws with direct drive. Measuring with absolute encoder to ensure high rigidity and positioning accuracy without backlash.

- Z-axis is equipped with box guideway reinforced through induction hardening process, precision ground and FEM analysis to offer superb cutting rigidity and short force flow

- The work table is precisely ground before assembled to ensure DCV series excellent machining results

- Isolated Direct Drive Design

- 10,000rpm IDD spindle driven by 22kW dual step AC digital spindle motor is able to reach max. 36.04kgf-m torque output at 500rpm.

- Unique IDD design offers low spindle vibration and optimal heat isolation that results in excellent accuracy after longterm operation.

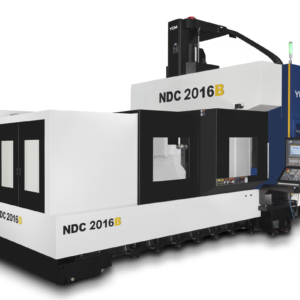

YCM NDC2016B

- A-ribbed base structure with multiple supporting points provides X-axis with the best straightness

- Work table fully supported by base provides perfect dynamic accuracy

- One piece high rigidity column offers low deformation, providing Y-axis with the best straightness

- Wide span saddle provides both horizontal and vertical support which decentralizes the load caused from head weight and spindle during machining

- Roller type linear guideways on both X/Y-axis provides low friction, non-backlash, high rigidity and high precision

- High damping boxway on Z-axis absorbs vibration, prolongs tool life and enhances surface precision

- Dual chip augers with conveyor offer efficient chip removal Simple plate metal design reduces chip accumulation

YCM NDC2018-AHC

- Self-manufactured gearbox provides high torque for both vertical and horizontal machining

- High rigidity octagonal milling head design

- Quiet precision grounded bevel gear, adopts oil-mist lubrication to reduce heat

- Large diameter toothed clutches provide high machining stability, precision and rigidity

- 4 independent pull studs with high clamping force

- 90°angle head anti-drop safety mechanism

- Optional coolant through spindle (CTS) for both vertical/ 90°angle head

- Rotary head chamber design reduces space and provides rapid head change

- Automatic vertical / horizontal head change mechanism

- Reduce time for both fixture producing and workpiece installation, improving production efficiency

- Multi-face machining in one step increases machining efficiency and precision

- Vertical / Horizontal tool change system provides fast tool change, sensors and sequence scanning ensures tool change stability

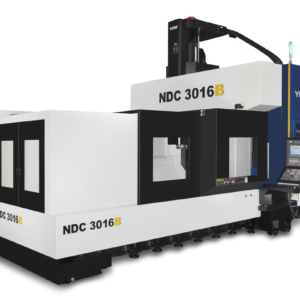

YCM NDC3016B

- A-ribbed base structure with multiple supporting points provides X-axis with the best straightness

- Work table fully supported by base provides perfect dynamic accuracy

- One piece high rigidity column offers low deformation, providing Y-axis with the best straightness

- Wide span saddle provides both horizontal and vertical support which decentralizes the load caused from head weight and spindle during machining

- Roller type linear guideways on both X/Y-axis provides low friction, non-backlash, high rigidity and high precision

- High damping boxway on Z-axis absorbs vibration, prolongs tool life and enhances surface precision

- Dual chip augers with conveyor offer efficient chip removal Simple plate metal design reduces chip accumulation

YCM NDC3018B-AHC

- Self-manufactured gearbox provides high torque for both vertical and horizontal machining

- High rigidity octagonal milling head design

- Quiet precision grounded bevel gear, adopts oil-mist lubrication to reduce heat

- Large diameter toothed clutches provide high machining stability, precision and rigidity

- 4 independent pull studs with high clamping force

- 90°angle head anti-drop safety mechanism

- Optional coolant through spindle (CTS) for both vertical/ 90°angle head

- Rotary head chamber design reduces space and provides rapid head change

- Automatic vertical / horizontal head change mechanism

- Reduce time for both fixture producing and workpiece installation, improving production efficiency

- Multi-face machining in one step increases machining efficiency and precision

- Vertical / Horizontal tool change system provides fast tool change, sensors and sequence scanning ensures tool change stability

YCM NDC3022B

- Highly rigid box structure head design, effectively resists deformation and vibration during heavy cutting.

- Extra wide column base with boots design prevents the headstock from leaning forward.

- Work table fully supported by base provides perfect dynamic accuracy.

- The gear box is self-made which is powerful 2-step gear transmission as standard, with oil cooling lubrication that prevents temperature rise and noise.

- X-axis adopts direct gear drive that provides high torque, high transmission efficiency and low backlash.

- Z-axis head is boxway design that shows high rigidity and high damping, effectively avoids overhang, and vibration issues.

- Wide span saddle enhances stabilization. With rigid beam and columns configuration, it provides Y-axis with the best straightness.

- Y-axis and Z-axis adopt ball screw and flexible direct design,without blacklash and belt drive issues.

YCM NDC4016B

- A-ribbed base structure with multiple supporting points provides X-axis with the best straightness

- Work table fully supported by base provides perfect dynamic accuracy

- One piece high rigidity column offers low deformation, providing Y-axis with the best straightness

- Wide span saddle provides both horizontal and vertical support which decentralizes the load caused from head weight and spindle during machining

- Roller type linear guideways on both X/Y-axis provides low friction, non-backlash, high rigidity and high precision

- High damping boxway on Z-axis absorbs vibration, prolongs tool life and enhances surface precision

- Dual chip augers with conveyor offer efficient chip removal Simple plate metal design reduces chip accumulation

YCM NDC4018B-AHC

- Self-manufactured gearbox provides high torque for both vertical and horizontal machining

- High rigidity octagonal milling head design

- Quiet precision grounded bevel gear, adopts oil-mist lubrication to reduce heat

- Large diameter toothed clutches provide high machining stability, precision and rigidity

- 4 independent pull studs with high clamping force

- 90°angle head anti-drop safety mechanism

- Optional coolant through spindle (CTS) for both vertical/ 90°angle head

- Rotary head chamber design reduces space and provides rapid head change

- Automatic vertical / horizontal head change mechanism

- Reduce time for both fixture producing and workpiece installation, improving production efficiency

- Multi-face machining in one step increases machining efficiency and precision

- Vertical / Horizontal tool change system provides fast tool change, sensors and sequence scanning ensures tool change stability

YCM NDC4022B

- Highly rigid box structure head design, effectively resists deformation and vibration during heavy cutting.

- Extra wide column base with boots design prevents the headstock from leaning forward.

- Work table fully supported by base provides perfect dynamic accuracy.

- The gear box is self-made which is powerful 2-step gear transmission as standard, with oil cooling lubrication that prevents temperature rise and noise.

- X-axis adopts direct gear drive that provides high torque, high transmission efficiency and low backlash.

- Z-axis head is boxway design that shows high rigidity and high damping, effectively avoids overhang, and vibration issues.

- Wide span saddle enhances stabilization. With rigid beam and columns configuration, it provides Y-axis with the best straightness.

- Y-axis and Z-axis adopt ball screw and flexible direct design,without blacklash and belt drive issues.

YCM NDC4022B-AHC

- Highly rigid box structure head design, effectively resists deformation and vibration during heavy cutting.

- Extra wide column base with boots design prevents the headstock from leaning forward.

- Work table fully supported by base provides perfect dynamic accuracy.

- X-axis adopts direct gear drive that provides high torque, high transmission efficiency and low backlash.

- Z-axis head is boxway design that shows high rigidity and high damping, effectively avoids overhang, and vibration issues.

- Wide span saddle enhances stabilization. With rigid beam and columns configuration, it provides Y-axis with the best straightness.

- Y-axis and Z-axis adopt ball screw and flexible direct design, without blacklash and belt drive issues.

- Self-manufactured gearbox with powerful 2-step gear transmission provides high torque for both vertical and horizontal machining.

- The gearbox with oil cooling lubrication that prevents temperature rise and noise.

- High rigidity octagonal milling head design

- Quiet precision grounded bevel gear, adopts oil-mist lubrication to reduce heat.

- Large diameter toothed clutches provide high machining stability, precision and rigidity.

- 4 independent pull studs with high clamping force

- 90° angle head anti-drop safety mechanism

- Optional coolant through spindle (CTS) for both vertical/ 90°angle head

- Rotary head chamber design reduces space and provides rapid head change.

- Automatic vertical / horizontal head change mechanism.

- Reduce time for both fixture producing and workpiece installation, improving production efficiency.

- Multi-face machining in one step increases machining efficiency and precision.

- Vertical / Horizontal tool change system provides fast tool change, sensors and sequence scanning ensures tool change stability.

YCM NTC-2000Y/LY

- 30°One-piece Slanted Bed Design : Extends the space for chips removal.

- Cross type ribs inside the base design provides the best rigidity. Durable Meehanite casting is adopted to simulate the structural deformation of the body under various conditions, integrated with YCM hand scrapping skills for box guideways, which ensures the best accuracy and lifetime.

- X/Z-axis boxway design with wear-resistant pad strengthens rigidity and damping capacity for reducing vibration.

- Hole through draw bar for bars of Ø65mm (8″) & Ø51mm (6″)

- The spindle is equipped with position encoder to detect speed and correct position.

- With milling function spindle, the indexing accuracy is up to 0.001°.

- Integrated Y-axis function with live tooling turret for X, Y, Z feeding, which is best for complex machining. The orthogonal Y-axis is designed for maintaining machining accuracy.

- Except for standard manual tailstock, programmable tailstock and servo tailstock are available.

YCM NTC-2000LSY

- 30°One-piece Slanted Bed Design : Extends the space for chips removal.

- Cross type ribs inside the base design provides the best rigidity. Durable Meehanite casting is adopted to simulate the structural deformation of the body under various conditions, integrated with YCM hand scrapping skills for box guideways, which ensures the best accuracy and lifetime.

- X/Z-axis boxway design with wear-resistant pad strengthens rigidity and damping capacity for reducing vibration.

- Hole through draw bar for bars of Ø65mm (8″) & Ø51mm (6″)

- The spindle is equipped with position encoder to detect speed and correct position.

- With milling function spindle, the indexing accuracy is up to 0.001°.

- Integrated Y-axis function with live tooling turret for X, Y, Z feeding, which is best for complex machining. The orthogonal Y-axis is designed for maintaining machining accuracy.

- Except for standard manual tailstock, programmable tailstock and servo tailstock are available.

YCM GT200B

- The box-type design offers a ultra-wide base structure, high quality MEEHANITE® castings, oversize hardened & ground boxed ways to ensure the best machining performance by eliminating structural distortion and deformation under heavy machining conditions.

- The tailstock is supported by hardened and ground boxed ways that is structurally one-piece with the machine base, which ensures the best structural rigidity.

- The oversize quill supports heavy workpieces while maintaining machining accuracy.

- Optional live quill is ideal for high-speed, high production environment.

- Automatic Tool Length Measurement (opt.)

- Automatic Bar-feeder System (opt.)

- Automatic Parts Catcher (opt.) and Transfer System (opt.)

- Oversize hardened and ground box ways, ballscrew and bearings are essential requirements for enhancing the axial and radial cutting rigidity.

- High torque spindle motor provides the necessary power for roughing operation on tough material at low spindle speed.

- High quality chuck with powerful hydraulic system ensures machining rigidity and accuracy.

- Pressure sensors are added to hydraulic system for monitoring clamping force of chuck, assuring the proper clamping of heavy parts.

- All spindles are strictly assembled in temperature controlled room, and proven through rigorous run-in test to assure the highest quality and reliability.The unique quill-type spindle cartridge designed for easy maintenance and repair if necessary.

- Reinforced ventilation is located throughout the spindle head to minimize thermal growth.

- Effective exhaust fans are installed on the spindle headstock to remove the heat generated from long running hours.

- High performance piston pump and radiation system are added to control the temperature of hydraulic oil, which minimize the thermal impact of hydraulic system.

- Isolated coolant tanks eliminate the effect of high coolant temperature after long running hours, which reduces structural deformation.

- The spindle motor sits outside of the machine base to isolate the heat generated from spindle motor after long operations.

- Low heat generated work lamp is installed to minimize temperature impact.

YCM GT200MA

- The box-type design offers a ultra-wide base structure, high quality MEEHANITE® castings, oversize hardened & ground boxed ways to ensure the best machining performance by eliminating structural distortion and deformation under heavy machining conditions.

- The tailstock is supported by hardened and ground boxed ways that is structurally one-piece with the machine base, which ensures the best structural rigidity.

- The oversize quill supports heavy workpieces while maintaining machining accuracy.

- Optional live quill is ideal for high-speed, high production environment.

- Automatic Tool Length Measurement (opt.)

- Automatic Bar-feeder System (opt.)

- Automatic Parts Catcher (opt.) and Transfer System (opt.)

- Oversize hardened and ground box ways, ballscrew and bearings are essential requirements for enhancing the axial and radial cutting rigidity.

- High torque spindle motor provides the necessary power for roughing operation on tough material at low spindle speed.

- The GT series is ideal for high productivity turning and milling with exceptional speed, power, and capacity.

- Heavy-duty Spindle Design and Durable Hydraulic Chuck

- High quality chuck with powerful hydraulic system ensures machining rigidity and accuraacy.

- Pressure sensors are added to hydraulic system for monitoring clamping force of chuck, assuring the proper clamping of heavy parts.

- All spindles are strictly assembled in temperature controlled room, and proven through rigorous run-in test to assure the highest quality and reliability.The unique quill-type spindle cartridge designed for easy maintenance and repair if necessary.

- Reinforced ventilation is located throughout the spindle head to minimize thermal growth.

- Effective exhaust fans are installed on the spindle headstock to remove the heat generated from long running hours.

- High performance piston pump and radiation system are added to control the temperature of hydraulic oil, which minimize the thermal impact of hydraulic system.

- Isolated coolant tanks eliminate the effect of high coolant temperature after long running hours, which reduces structural deformation.

- The spindle motor sits outside of the machine base to isolate the heat generated from spindle motor after long operations.

- Low heat generated work lamp is installed to minimize temperature impact.