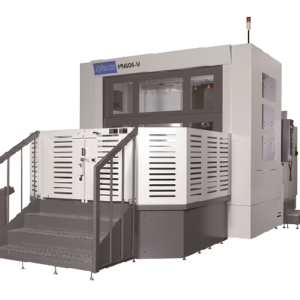

Niigata HN800V

HN800V Heavy Duty Boxway Horizontal Machining Center (HMC)

- Heavy duty boxway machining center with V-shaped guideways, hardened and ground.

- Precision straightness of motion, elimination of roll, pitch and yaw.

- Hand scraped squareness and perpendicularity for increased volumetric accuracy.

- Rapid speed of 50m/min or 1968 ipm.

- Solid meehanite cast iron machine frame.

- Outstanding stability, damping through extensive ribbing of machine frame.

- Gear driven spindles that general extremely high torque.

- Niigata’s mean workzone is the most generous in the industry.

Niigata HN100D-II

HN100D-II Heavy Duty Boxway Horizontal Machining Center

- Heavy duty boxway machining center with solid meehanite cast iron machine frame.

- Outstanding stability, damping through extensive ribbing of machine frame.

- Wide induction hardened boxways for long-term accuracy and rigidity.

- All axes hand scrapped by highly experienced technicians.

- Gear driven spindles that general extremely high torque.

- Niigata’s mean workzone is the most generous in the industry.

Niigata HN800V-Ti

HN800V-Ti Heavy Duty Boxway Machining Center (HMC) Designed for Machining Titanium and Other Hard Machining Materials

- Heavy duty boxway machining center designed for ultra low frequency machining.

- Hardened and ground V-shaped guideways.

- Precision straightness of motion, elimination of roll, pitch and yaw.

- Hand scraped squareness and perpendicularity for increased volumetric accuracy.

- Rapid speed of 50m/min or 1968 ipm.

- Solid meehanite cast iron machine frame.

- Outstanding stability, damping through extensive ribbing of machine frame.

- Gear driven spindles that general extremely high torque.

- Niigata’s mean workzone is the most generous in the industry.

Niigata HN100D-II-Ti

HN100D-II-Ti Heavy Duty Boxway Machining Center Designed for Machining Titanium and Other Hard Machining Materials

- Heavy duty boxway machining center designed for ultra low frequency machining.

- Solid meehanite cast iron machine frame.

- Outstanding stability, damping through extensive ribbing of machine frame.

- Wide induction hardened boxways for long-term accuracy and rigidity.

- All axes hand scrapped by highly experienced technicians.

- Gear driven spindles that general extremely high torque.

- Niigata’s mean workzone is the most generous in the industry.

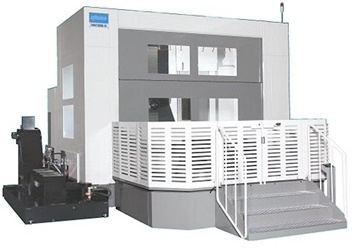

Niigata HN130D

HN130D Heavy Duty Boxway Horizontal Machining Center

- Heavy duty boxway machining center features solid meehanite cast iron machine frame.

- Outstanding stability, damping through extensive ribbing of machine frame.

- Wide induction hardened boxways for long-term accuracy and rigidity.

- All axes hand scrapped by highly experienced technicians.

- Gear driven spindles that general extremely high torque.

- Niigata’s mean workzone is the most generous in the industry.

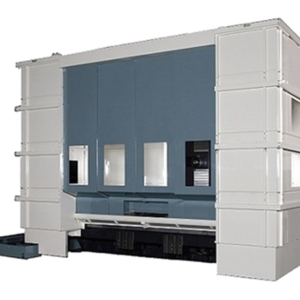

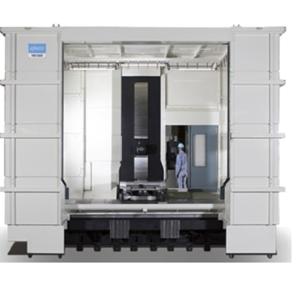

Niigata HN1600D

HN1600D Heavy Duty Boxway Machining Center

- Heavy duty boxway machining center features solid meehanite cast iron machine frame.

- Outstanding stability, damping through extensive ribbing of machine frame.

- Wide induction hardened boxways for long-term accuracy and rigidity.

- All axes hand scrapped by highly experienced technicians.

- Gear driven spindles that general extremely high torque.

- Niigata’s mean workzone is the most generous in the industry.

Niigata SPN503

SPN503 High-Speed Linear Roller Guide Horizontal Machining Center

- High-speed linear horizontal machining center features high torque & speed #50 taper spindle.

- Our Box in box (double box structure) achieves long-term volumetric accuracy.

- Solid base and simple 3-point leveling.

- Ultra rigid and high load type roller guideway system for X,Y,Z axis.

- Unique synchronous swing motion (SSM) reduces ATC time.

Niigata SPN701

SPN701 High-Speed Linear Roller Guide Horizontal Machining Center

- High-speed linear roller guide horizontal machining center features excellent machine accuracy and stability with a high torque/speed #50 taper spindle.

- Box in box (double box structure) achieves long-term volumetric accuracy.

- Solid base and simple 3-point leveling.

- Ultra rigid and high load type roller guideway system for X,Y,Z axis

- Unique synchronous swing motion (SSM) reduces ATC time.

Niigata SPN901

SPN901 High-Speed Linear Roller Guide Horizontal Machining Center

- High-speed linear roller guide horizontal machining center features excellent machine accuracy and stability with a high torque/speed #50 taper spindle.

- Box in box (double box structure) achieves long-term volumetric accuracy.

- Solid base and simple 3-point leveling.

- Ultra rigid and high load type roller guideway system.

- Unique synchronous swing motion (SSM) reduces ATC time.

Niigata N7

N7 High-Speed Linear HMC with 15 Inch Color LCD

- High-speed linear horizontal machining center with 15 inch color LCD.

- Box in box (double box structure) achieves long-term volumetric accuracy.

- Solid base and simple 3-point leveling.

- Excellent machine accuracy stability.

- Ultra rigid and high load roller guideway system.

Niigata HN800-S

HN800-S Boxway Horizontal Machining Center

- Hybrid boxway horizontal machining center with a combination of linear roller guides on X and Z axis and boxway guide system on Y axis.

- Speed, stability, vibration dampening are achieved at 41m/min or 1614 ipm.

- Heavy duty, high torque geared head spindle is standard.

- Wide range of spindle choices – standard, quill / bar, extreme high torque and 15,000 rpm 60 hp.

Niigata HN1000S

HN1000S Boxway Horizontal Machining Center

- Hybrid boxway horizontal machining center with a combination of linear roller guides on X and Z axis and boxway guide system on Y axis.

- Speed, stability, vibration dampening are achieved at 40m/min or 1574 ipm.

- Heavy duty, high torque geared head spindle is standard.

- Wide range of spindle choices – standard, quill / bar, exreme high torque and 15,000 rpm 60 hp.

Niigata HN1250S

HN1250S Boxway Horizontal Machining Center

- Hybrid boxway horizontal machining center with a combination of linear roller guides on X and Z axis and boxway guide system on Y axis.

- Speed, stability, vibration dampening are achieved at 40m/min or 1574 ipm.

- Heavy duty, high torque geared head spindle is standard.

- Wide range of spindle choices – standard, quill / bar, exreme high torque and 15,000 rpm 60 hp.

Niigata HN1600S

HN1600S Boxway Horizontal Machining Center

- Hybrid boxway horizontal machining center features largest work envelope in its class.

- Hybrid machining with a combination of linear roller guides on X and Z axis and boxway guide system on Y axis.

- Speed, stability, vibration dampening are achieved at 40m/min or 1574 ipm.

- Heavy duty, high torque geared head spindle is standard.

- Wide range of spindle choices – standard, quill / bar, exreme high torque and 15,000 rpm 60 hp.

Niigata HN50E-5X

HN50E-5X 5-Axis Horizontal Machining Center (5-Axis HMC)

- This 5-axis horizontal machining center features a rigid machine body.

- Machine base of HN63E – a rigid boxway machine with excellent stability and great damping characteristics.

- High torque spindle.

- Rigid trunnion table for low frequency machining.

- High load roller BRG and double-lead worm gear for A and B axes, high torque drive.

- Perfect for machining titanium and other hard machining materials.

- A variety of 5-axis machining support software.

Niigata HN63E-5X

HN63E-5X 5-Axis Horizontal Machining Center (5-Axis HMC)

- This 5-axis horizontal machining center features a rigid machine body.

- Machine base of HN63E – a rigid boxway machine with excellent stability and great damping characteristics.

- High torque spindle.

- Rigid trunnion table and low frequency machining.

- High load roller BRG and double-lead worm gear for A and B axes, high torque drive.

- Perfect for machining titanium and other hard machining materials.

- A variety of 5-axis machining support software.

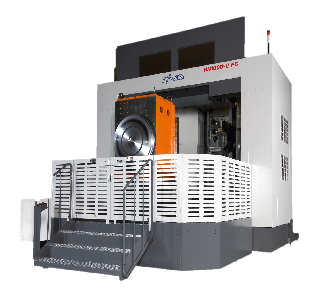

Niigata HN100D-II-FC

HN100D-II-FC Multi-Tasking Horizontal Machining Center (HMC)

- Multi-tasking horizontal machining center performs turning, facing, boring and milling, all in one machine and completely programmable.

- Rigid & solid machine body.

- Outstanding stability & vibration damping by thick machine base.

- Long-term accuracy and rigidity by wide induction hardened boxways that are skillfully scraped by Niigata.

- Largest work zone in its class.

- Long stroke.

- Wide machining range.

- Standard facing head or twin facing tool head.

Niigata HN130D-FC

HN130D-FC Multi-Tasking HMC with Largest Work Zone

- Multi-tasking horizontal machining center (HMC) with largest work zone performs turning, facing, boring and milling, all in one machine and completely programmable.

- Outstanding stability & vibration damping by thick machine base.

- Long-term accuracy and rigidity by wide induction hardened boxways that are skillfully scraped by Niigata.

- Largest work zone in its class.

- Long stroke.

- Wide machining range.

- Standard facing head or twin facing tool head.

Niigata HN1600D-FC

HN1600D-FC Multi-Tasking Horizontal Machining Center (HMC)

- Multi-tasking horizontal machining center performs turning, facing, boring and milling, all in one machine and completely programmable.

- Rigid & solid machine body.

- Outstanding stability & vibration damping by thick machine base.

- Long-term accuracy and rigidity by wide induction hardened boxways that are skillfully scraped by Niigata.

- Largest work zone in its class.

- Long stroke.

- Wide machining range.

- Standard facing head or twin facing tool head.

Niigata HN100D-II-BAR

HN100D-II-BAR Horizontal Machining Center with Bar/Quill Style Spindle

- Horizontal machining center with bar/quill style spindle features a spindle bar diameter of 130mm.

- Bar/Quill machining is strongly supported by Niigata HN series rigid machine body.

- Solid and tough machine body.

- Outstanding stability & vibration damping by thick machine base.

- Long-term accuracy and rigidity by wide induction hardened boxways that are skillfully scraped by Niigata.

- High-torque spindle with gear drive.

Niigata HN1250-S-BAR

HN1250-S-BAR Hybrid Machining Center with Boring Function

- A hybrid machining center with boring function.

- Harmony of rigidity from boxway system (Y axis) and high productivity from roller guide (X,Z axis).

- Rapid traverse 41m/min for ultra heavy work.

- Outstanding stability & vibration damping by thick machine base.

- Spindle diameter ɸ 130.

- Solid machine base of HN series suitably supports powerful boring machining.

Niigata HN1600-S-BAR

HN1600-S-BAR HMC with Largest Work Envelope in Its Class

- HMC with largest work envelope in its class.

- Harmony of rigidity from boxway system (Y axis) and high productivity from roller guide (X,Z axis).

- Rapid traverse 30m/min for ultra heavy work.

- Outstanding stability & vibration damping by thick machine base.

- Hi-torque heavy duty spindle.

- Wide machining range.

Niigata HN1000-S-BAR

HN1000-S-BAR Hybrid HMC with Boring Function, Long Stroke

- A hybrid HMC with boring function, long stroke.

- Harmony of rigidity from boxway system (Y axis) and high productivity from roller guide (X,Z axis).

- Rapid traverse 41m/min for ultra heavy work.

- Outstanding stability & vibration damping by thick machine base.

- Spindle diameter ɸ 130, Bar/Quill stroke 535 mm.

- Solid machine base of HN series suitably supports powerful boring machining.

- Wide machining range.

Niigata ICC (Intelligent Cell Controller) System

ICC (Intelligent Cell Controller) System is Niigata’s original system controller with which FMS & Robot System that Niigata offers are operated.

ICC (Intelligent Cell Controller) System

Simple & Efficient

- ICC controller is based on PC and easy to be operated; machining program per pallet, machining date adjustment to the situation, etc., as well as date update and renewal of the ICC system.

System Protection

- Save the same data on some hard disk drive simultaneously

- Date back-up

- Dust-proof/Drip-proof structure

- Box cooler equipped

Quick Recovery from Parts Breakdown

- The components of the system are standard parts of PC manufacturer and are easy to be purchased.

Example of ICC Option (Production Control Function)

- The components of the system are standard parts of PC manufacturer and are easy to be purchased.

- Recognizing non-cutting time and/or dead time is the first step to make more efficient line operation possible.

Niigata New Generation Operation Panel

Horizontal Machining Center Operation Panel

Our new generation horizontal machining center operation panel with 15” color LCD comes standard. The control panel is strategically located at the most convenient position and the operator can easily monitor the workpiece and machining operations, while utilizing the control functions and includes:

- Universal serial bus port

- Memory card slot

- RS-232C port

- Ethernet communication

- Diagnostic & history

- Automatic ATC recovery (SPN Series only)

Niigata HN-FC Twin Facing Head Horizontal Machining Centers

Niigata first introduced twin facing head horizontal machining centers at IMTS in 1996.

- New FC head with twin facing locations for additional stroke.

- Variety of machining capabilities: turning, drilling, tapping, boring and milling are feasible by U-axis for turning and W-axis for machining automatically.

- Allows turning diameter from 0” up to 40”.

- U -axis constant torque 1098 ft.lbs.

- U-axis has constant surface footage speeds up to 600 RPM.

YCM DCV2012A

- One-piece Column

- One-piece Base

- Roller type guideways on X/Y axis

- Horizontal and vertical support of the headstock

- Direct drive motors on 3 axes reduce backlash and ensure perfect axial accuracy

- Three axes adopt highly responsive servo motor, configuring ball screws with direct drive. Measuring with absolute encoder to ensure high rigidity and positioning accuracy without backlash.

- Z-axis is equipped with roller type guideway and 6 slider blocks to enhance cutting rigidity and smooth movement during 3D contouring operations

- The work table is precisely ground before assembled to ensure DCV series excellent machining results

- DCV2012A is equipped with YCM made built-in motorized spindle delivering 20,000rpm high speed. The ultra smooth movement achieves various machining results.

- Patented circulated cooling system

- Patented suppressing vibration design

- Floating design of rear bearing

- Bearing with micro oil-air lubrication system

- BBT40 with simultaneous taper and flange contact design

YCM DCV2018A-5AX

- One-piece Column

- One-piece Base

- Ultimate rigidity and proportion of the headstock

- Internal double A type ribbed bed design through FEM analysis offers full support for table.

- 1,800 mm distance between columns increases the stability of machine

- Roller type linear guideways on X / Y / Z-axis.

- Y axis linear guideways design with large span with horizontal and vertical directions which can take the saddle weight and machining force.

- Direct driven motors on Y / Z-axis reduce backlash and ensure perfect axial accuracy.

- X-axis is gearbox driven.

- The work table is precisely ground before assembled to ensure DCV series excellent machining results.

- 8 tons maximum table machining loading.

- DD motor drive, no backlash.

- B/C axis rotary speed 100 rpm

- C-axis includes three roller bearings to increase rigidity and accuracy.

- B-axis high rigidity and high accuracy cross roller bearing.

- Heidenhain accuracy encoder included as standard.

- Pneumatic positioning clamping equipment.

- Over travel protection design.

- B-axis anti-drop function at power outage.

- Deliver maximum spindle speed of up to 18,000 rpm driven by 70 kW motor.

YCM DCV3016B

- X-axis is directly driven by gearbox offering smooth axial response and high torque

- Roller type guideways on X/Y axis

- Y-axis is supported by 3 roller type guideways and 6 slider blocks to offer ultimate cutting rigidity

- Horizontal and vertical support of the headstock

- Hardened and ground box guideway on Z-axis enlarges the contact interface for high machining stability

- With Hi-lo Gear Transmission

- 4,500rpm spindle speed is standard with 2-step gear transmission.

- The spindle incorporates roller type spindle bearings for extremely high cutting rigidity.

- The 2-step gear transmission provides 88.87kgf-m torque output at 241rpm ideal for machining hard material.

- One-piece Column

- One-piece Base

- Rigid proportion of the headstock

YCM DCV3018A-5AX

- One-piece Column

- One-piece Base

- Ultimate rigidity and proportion of the headstock

- Internal double A type ribbed bed design through FEM analysis offers full support for table.

- 1,800 mm distance between columns increases the stability of machine

- Roller type linear guideways on X / Y / Z-axis.

- Y axis linear guideways design with large span with horizontal and vertical directions which can take the saddle weight and machining force.

- Direct driven motors on Y / Z-axis reduce backlash and ensure perfect axial accuracy.

- X-axis is gearbox driven.

- The work table is precisely ground before assembled to ensure DCV series excellent machining results.

- 10 tons maximum table machining loading.

- DD motor drive, no backlash.

- B/C axis rotary speed 100 rev/min.

- C-axis includes three roller bearings to increase rigidity and accuracy.

- B-axis high rigidity and high accuracy cross roller bearing.

- Heidenhain accuracy encoder included as standard.

- Pneumatic positioning clamping equipment.

- Over travel protection design.

- B-axis anti-drop function at power outage.

- Deliver maximum spindle speed of up to 18,000 rpm driven by 56/70kW motor