Newall DP700 Digital Readout

The DP700 is the latest in Newall’s line of a powerful and intuative DROs. The unit is housed in a rugged, ergonomically designed casting. The DRO features all of the essential functions for milling, boring, turning, grinding, and general machining operations.

- Available in 1, 2 or 3 axes

- Clean, Crisp, Easy to Read, LEDs

- Intuitive Message Window

- Long Life Membrane Keypad

- Solid cast construction

- Safe, Low Voltage Power Supply (UL)

- Panel Mount Version Available

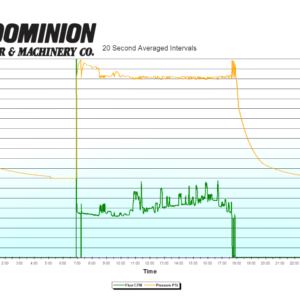

Flow Studies and Air Audits

Our dedicated system design team specializes in flow studies and air audits. We will consult with you to maximize your savings from your Kaeser compressed air system. Contact us today to get started on your new system.

Chevalier FSG CNC Series

The FSG-H818CNC & FSG-B818CNC grinding machines are high precision, high efficiency multi purpose CNC profile grinders. These machines are designed to meet current and future grinding requirements such as intricate profiles, mold components and are well suited for parts of aircraft, automobile, electronic, medical, machine tool, and defense industries.

Chevalier Smart Series

The SMART-III Series is capable of producing “mirror” finishes on highly accurate workpieces, which produce microfinishes of 5 RMS or better. The positioning accuracy 0.00015″ to 0.00023″ and the repeatability is 0.00012″ to 0.00023″. The SMART-III’s movements are programmable in increments of 0.0001″.

Chevalier FSG SP Manual Series

These models have all the features of the Chevalier M Series Grinders but with heavier and more rigid construction.

Chevalier Manual M Series

M Series Standard Tool Room Surface Grinder.

Chevalier FSG-ADIII Automatic Series

The FSG-ADIII series features a new user-friendly touch-screen control with standard surface grinding programs and a plunge grinding cycle. There is also an optional crisscross or zigzag and a CBN dressing cycle. So simple and user-friendly, all skill levels can operate this series of ADIII controllers.

The fully automatic grinding mode consists of rough- and fine-grinding cycles, switching from rough-grinding down-feed increments to fine-grinding down-feed increments at preset points during the cycle. This crossfeed also switches from a rough to fine cross-feed increment, which results in a finer surface finish and finer accuracy.

• No more cycle stops or prepping the wheel

• Faster cycle times

• Chevalier control: touch screen

• 3-Axes Fully Automatic

• Table size: up to 16″W x 40″L

• Auto. dressing and compensation optional

• Elevation is driven by servo motor

• 3-Axes needle roller way

• Max. grinding sizes: up to 16″ x 40″

• Spindle power: up to 10 HP, greater spindle HP available

Chevalier FSG Semi-Automatic Series

• 2A 2-Axes and X-Axis driven by Hydraulic system • Table size: up to 12”W x 24”L • Z-Axis with Double “V” ways and electric motor • Hand scrapped Turcite-B used on Z- and Z-Axes • Spindle speed: 3500/1750rpm • … Read More

Chevalier FSG-2A818/3A818 Automatic Series

Series features a smooth and accurate movement with low friction to ensure high accuracy and longer way life. The proximity switches let the operator set the right stroke for each workpiece. The precision 0.0001″ graduated microfeed device (worm and wormgear design) ensures precise positioning of the cross axis.

• Vertical feed is driven by AC motor and equipped with automatic downfeed device and manual microdownfeed device

• Cross movement is driven by AC motor

• Longitudinal table movement is driven by hydraulic unit

• Table traverses on hardened & ground guideways w/ steel ball bearings

• Turcite-B laminated and hand-scraped machine slideways

• Table reversing mechanism

• Elevating microfeed device

Chevalier CGP Cylindrical Series

Universal cylindrical grinder with heavy-duty hydrostatic spindle bearings

• Hydrostatic spindle bearings for precision grinding

• Precision ballscrew driven by AC digital servo motor

• Mitsubishi PLC control with touch screen operation

• Wheelhead repeatability of ±0.000050”

• Variable speed workhead 16-450rpm, 0.8kw AC servo motor

• Table travels on one V, one flat guideway

• Fully ribbed, high grade Meehanite cast iron

• Tailstock center is capable of absorbing thermal expansion of workpiece

• Rough grinding, fine grinding and sparkout in one setting

• Wheel head retract to original setting point after grinding cycle is complete

Chevalier CGP Hydraulic Cylindrical Series

Hydraulic Cylindrical Grinder with heavy-duty hydrostatic spindle bearings

• Hydrostatic bearings for precision grinding

• Precision ballscrew with AC digital motor

• Mitsubishi PLC control with touch screen

• Wheelhead repeatability ±0.000050″

• Variable speed workhead 16-450rpm

• Automatic dresser w/ compensation (opt)

• Internal grinding attachment (opt)

Compressor Station®

Compressor Station® is Dominion Air’s exclusive solution to the all-in-one compressed air system.

Featuring industrial-grade Kaeser® compressors, dryers, filters, and automatic drains, Steelfab® tanks, and WIKA® gauges.

Each Compressor Station® is custom designed, engineered, and built to meet your exact requirements.

From 21 to 176 CFM, in single compressor and duplex configurations.

Are you ready to build your custom Compressor Station®?

ContainAir®

Custom, Turnkey, Portable. Package compressed air solutions manufactured by Dominion Air

We custom design each ContainAir system to fit your needs.

- Compact 20′ containers up to a 40′ high box

- Up to 300 HP Kaeser® compressors

Contact us today to build your custom package air solution.

Kingston CL-38 Series

A powerful and rigid CNC lathe for versatile applications.

The CL-38 is a perfect machine for heavy duty turning and high precision machining. Designed to be a universal CNC turning lathe, it is suitable for the medium to large workpiece, the barstock, and the shaft. Incorporated with a choice of turrets, it offers flexible working modes in both production and non-production jobs.

• FANUC 0iTC, FANUC 0iTD

• Spindle motor 30 HP

• V8 front turret and H6 rear turret

• Single or double chuck ready

26″ Swing

Choice of distance between centers:

40″ / 60″ / 80″ / 120″ / 160″

Spindle bore: 4.7″”, 7.08””

Kingston CL-68/78 Series

45″/59” Swing

Choice of distance between centers:

80″ / 120″ / 160″ / 200″ / 240″

Spindle bore: 7”, 10”, 14.7″

• FANUC 0iTD

• Spindle motor 50 HP

• V8 front turret and H4 rear turret

• Single or double chuck ready

Kingston HK-HG Series

Swing over bed: HK: 30″ or 34″

Swing over bed: HG: 34″ or 40″

Choice of distance between centers:

80″ / 120″ / 160″ / 200″/ 240″ / 280″

Spindle bore: HK 12.5″, HG 14.5″

• 20HP motor and wiring complete

• 4-way rapid traverse

• Coolant system

• Semi-air threading attachment

• Hardened and grounded bedways

• Double chuck ready

Kingston HP-HPX Series

34” / 40″ Swing over bed

Choice of distance between centers:

80″ / 120″ / 160″ / 200″ / 240″ / 280″

Spindle bore: 7.09″ / 9.25″

• 30HP motor and wiring complete

• 4-way rapid traverse

• Coolant system

• Hardened and grounded bedways

• Double chuck ready

Kingston HR Series

30” / 34“ / 40” Swing over bed

Choice of distance between centers:

80” / 120” / 160” / 200” / 240” / 280”

Spindle bore: 4 1/16

• 20HP motor and wiring

• 4-way rapid traverse

• Coolant system

• Hardened and grounded bedways

Kingston HD Series

22” / 26“ Swing over bed

Choice of distance between centers:

60” / 90” / 120” / 160”

Spindle bore: 4.0625”

• 10 HP or 15 HP motor

• Center sleeve M.T. #7×5

• Dead center M.T. #5

• Multi-position longitudinal stop

• Complete coolant system

• Hardened and grounded bedways

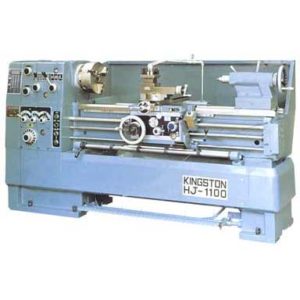

Kingston HJ Series

17“ Swing over bed

Choice of distance between centers:

43.5” / 67”

Spindle bore: 2.25”

• 7.5 HP motor

• 10″ 3-jaw scroll chuck

• Steady rest

• Coolant system

• Hardened and grounded bedways

Kryosec Refrigerated Dryers

TAH – TBH series

Flow rate: 12 to 77 scfm

Exceptionally reliable and ultra compact

Kryosec refrigerated dryers typify renowned ‘Made in Germany’ quality. They provide dependable drying in ambient temperatures up to 122 °F and ensure high efficiency performance through their low maintenance design and the minimal pressure loss heat exchanger system. With their compact footprint they are exceptionally versatile and are ideal for locations where space is at a premium.

Retrofit EMX, KMX, SMX Kits

A great productivity investment

The more frugal you are, the more painful it should be to watch your people spend their time unproductively. The cost of the ProtoTRAK CNC is trivial when compared to the cost of the person standing in front of the machine. If you are going to keep and use the machine, retrofit it.

Even a machine that has some wear can be a good candidate for a retrofit. Ballscrews will be installed in the table and saddle and electronic machine tool error calibration and backlash compensation routines help maintain accuracy. If the head is in good condition, you probably have a useful machine.

We only retrofit small knee mills and our expertise is honed by twenty years’ experience and over 15,000 successful retrofits. The retrofit kit includes everything: motors, CNC, hardware, ballscrews, fasteners, even the cable ties. It is installed in your shop in about a day by a factory-trained technician. Custom kits for dozens of machines are available in either two or three-axis CNC.

You shouldn’t stop investing in productivity until all your machinists are working as efficiently as possible. Retrofitting can be a cost-effective way for you to reach that goal.

Compressor Rentals

Dominion Air has the equipment for your temporary compressed air needs.

From small jobs to large industrial operations, our diesel and electric rental fleet

TRAK DPMRX2

TRAK DPMRX2

Like all TRAK DPMRX Series Bed Mills, the DPMRX2 features:

- ProtoTRAK RMX CNC integrated into the machine at the factory

- TRAKing® — control of program run

- Solid ram moves along the column providing mass for heavy cuts

- Generous Z-axis CNC travel

- Strong and rigid

- Efficient for any job: manual, 2-axis CNC or 3-axis CNC

- Standard electronic head for programmable spindle speeds and tapping

- Precision ground ballscrews installed in the table, saddle and column

- Manual quill with integrated quill and ram encoders

- Wide way surfaces are hardened and ground, slideways are Turcite®coated

- Real handwheels so you can work manually

With These Important Differences:

- 49″ x 9″ table size

- 31.75″ X axis / 16″ Y axis / 25.5″ Z axis travel

- 3 HP continuous spindle motor

- R8 spindle taper

TRAK DPMRX3

Like all TRAK DPMRX Series Bed Mills, the DPMRX3 features:

- ProtoTRAK RMX CNC integrated into the machine at the factory

- TRAKing® — control of program run

- Solid ram moves along the column providing mass for heavy cuts

- Generous Z-axis CNC travel

- Strong and rigid

- Efficient for any job: manual, 2-axis CNC or 3-axis CNC

- Standard electronic head for programmable spindle speeds and tapping

- Precision ground ballscrews installed in the table, saddle and column

- Manual quill with integrated quill and ram encoders

- Wide way surfaces are hardened and ground, slideways are Turcite®coated

- Real handwheels so you can work manually

With These Important Differences:

- 50″ x 10″ table size

- 31.5″ X axis / 17″ Y axis / 25.81″ Z axis travel

- 5 HP continuous spindle motor

- 40 taper spindle

TRAK DPMRX5

Like all TRAK DPMRX Series Bed Mills, the DPMRX5 features:

- ProtoTRAK RMX CNC integrated into the machine at the factory

- TRAKing® — control of program run

- Solid ram moves along the column providing mass for heavy cuts

- Generous Z-axis CNC travel

- Strong and rigid

- Efficient for any job: manual, 2-axis CNC or 3-axis CNC

- Standard electronic head for programmable spindle speeds and tapping

- Precision ground ballscrews installed in the table, saddle and column

- Manual quill with integrated quill and ram encoders

- Wide way surfaces are hardened and ground, slideways are Turcite®coated

- Real handwheels so you can work manually

With These Important Differences:

- 50″ x 12″ table size

- 40″ X axis / 20″ Y axis / 25.81″ Z axis travel

- 5 HP continuous spindle motor

- 40 taper spindle

- Almost 4″ quill diameter

- Rapid speeds of 400 IPM on X and Y, 250 IPM on Z

- Standard Electronic Handwheels with selectable fine/coarse handwheel resolution

TRAK DPMRX7

Like all TRAK DPMRX Series Bed Mills, the DPMRX7 features:

- ProtoTRAK RMX CNC integrated into the machine at the factory

- TRAKing® — control of program run

- Solid ram moves along the column providing mass for heavy cuts

- Generous Z-axis CNC travel

- Strong and rigid

- Efficient for any job: manual, 2-axis CNC or 3-axis CNC

- Standard electronic head for programmable spindle speeds and tapping

- Precision ground ballscrews installed in the table, saddle and column

- Manual quill with integrated quill and ram encoders

- Wide way surfaces are hardened and ground, slideways are Turcite®coated

- Real handwheels so you can work manually

With These Important Differences:

- 76″ x 14″ table size

- 60″ X axis / 23″ Y axis / 24.25″ Z axis travel

- 5 HP continuous spindle motor

- 40 taper spindle

- 56″ quill diameter

- Rapid speeds of 400 IPM on X and Y, 250 IPM on Z

- Standard Electronic Handwheels with selectable fine/coarse handwheel resolution

- 7,480 lbs. of machine mass

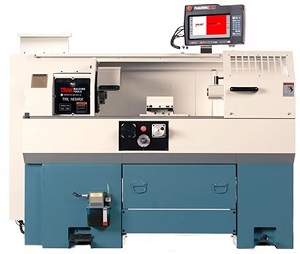

TRAK TRL 1630RX

Like all TRAK RX Lathes, the TRL 1630RX features:

- ProtoTRAK RLX CNC integrated into the machine at the factory

- Manual or CNC operation

- Electronic handwheels and jogstick

- Brushless servo motors

- Inverter-duty spindle drive

- Programmable spindle speeds

- Constant Surface Speed (CSS) Programming

- Inch Per Revolution (IPR) Programming

- Optional TRAKing® for manual control of CNC programs

- Optional turret for automatic tool changes

With these important differences:

- 16″ swing, 30″ between centers

- Spindle through hole of 2.12″

- 150-2500 rpm

- Ideal for small parts, but a generous swing for versatility

TRAK TRL 1630HS-RX

Like all TRAK RX Lathes, the TRL 1630HS-RX features:

- ProtoTRAK RLX CNC integrated into the machine at the factory

- Manual or CNC operation

- Electronic handwheels and jogstick

- Brushless servo motors

- Inverter-duty spindle drive

- Programmable spindle speeds

- Constant Surface Speed (CSS) Programming

- Inch Per Revolution (IPR) Programming

- Optional TRAKing® for manual control of CNC programs

- Optional turret for automatic tool changes

With these important differences:

- 16″ swing, 30″ between centers

- Spindle through hole of 1.57″

- 150-4000 rpm

- At home in a lab or wherever smaller parts are made