FFG DMC DL 5GH

DL 5GH

Travel (X/Z)(mm)(inch) 300 x 235 (11.81″ x 9.25″)

Guideway Type Dove-tail

Spindle speed(rpm) 6,000 rpm

Max. No. of Tool(pcs) 5 pcs

FFG DMC Q5-2S

Q5-2S

Travel (X/Z)(mm)(inch) 200 x 235 (11.81″ x 9.25″)

Guideway Type Dove-tail

Spindle speed(rpm) 6,000 rpm

Max. No. of Tool(pcs) 5 pcs

FFG DMC DL 6T

DL 6T

Travel (X/Z)(mm)(inch) 160 x 350 (6.30″ x 13.78″)

Guideway Type LM Guide

Spindle speed(rpm) 6,000 rpm

Max. No. of Tool(pcs) 10 (6+6)

FFG DMC DL 8TH

DL 8TH

Travel (X/Z)(mm)(inch) 160 x 520 (6.30″ x 20.47″)

Guideway Type LM Guide

Spindle speed(rpm) 4,500 rpm

Max. No. of Tool(pcs) 10

FFG DMC DL 10TMH

DL 10TMH

Travel (X/Z)(mm)(inch) 160 x 380 (6.30″ x 14.96″)

Guideway Type LM Guide

Spindle speed(rpm) 3,500 rpm

Max. No. of Tool(pcs) 12

FFG DMC DL 24TTGA

Main Specification

Axis Travel (X/Z)(mm)(inch) 190 x 200 (7.48″ x 7.87″)

Standard Chuck 8″

Max Turning Dia.(mm)(inch) 150 (5.91″)

Max Turning Length (mm)(inch) 150 (5.91″)

Loader Specification

Working Size (mm) 0D Ø250x150L / ID Ø250x100L

Working Size (inch) 0D Ø9.84″x59.06L / ID Ø9.84″x3.94″L

A/B/C-axis Speed (m/min)(ipm) 127/76/52 (5000/2992/2047)

Max. Handling Weight(kgf)(lbs) 8+8(17.64+16.64)

FFG DMC DL 24TTGB

Main Specification

Axis Travel (X/Z)(mm)(inch) 190 x 200 (7.48″ x 7.87″)

Standard Chuck 10″

Max Turning Dia.(mm)(inch) 250 (9.84″)

Max Turning Length (mm)(inch) 150 (5.91″)

Loader Specification

Working Size (mm) 0D Ø250x150L / ID Ø250x100L

Working Size (inch) 0D Ø9.84″x5.91L / ID Ø9.84″x3.94″L

A/B/C-axis Speed (m/min)(ipm) 127/76/52 (5000/2992/2047)

Max. Handling Weight(kgf)(lbs) 8+8(17.64+17.64)

FFG DMC DL 21MA

DL 21MA

Travel (X/Z) (mm) (inch) 200 x 410 mm (7.87″ x 16.14″)

Guideway Type Roller Guide Way

Spindle speed (rpm) 4,000 rpm

Max. No. of Tool (pcs) 12 pcs

FFG DMC DL 21LMA

DL 21LMA

Travel (X/Z) (mm) (inch) 200 x 550 mm (7.87″ x 21.65″)

Guideway Type Roller Guide Way

Spindle speed (rpm) 4,000 rpm

Max. No. of Tool (pcs) 12 pcs

FFG DMC DL 22LMA

DL 22LMA

Travel (X/Z) (mm) (inch) 200 x 550 mm (7.87″ x 21.65″)

Guideway Type Roller Guide Way

Spindle speed (rpm) 4,000 rpm

Max. No. of Tool (pcs) 12 pcs

FFG DMC DL 22LMB

DL 22LMB

Travel (X/Z) (mm) (inch) 200 x 550 mm (7.87″ x 21.65″)

Guideway Type Roller Guide Way

Spindle speed (rpm) 3,500 rpm

Max. No. of Tool (pcs) 12 pcs

FFG DMC DL 25

DL 25

Travel (X/Z) (mm) (inch) 230 x 1,130 (9.06″ x 44.49″)

Guideway Type BOX Way

Spindle speed (rpm) 3,500

Max. No. of Tool (pcs) 12

FFG DMC DL 40

DL 40

Travel (X/Z) (mm) (inch) 305 x 1,305 (12.01″ x 51.38″)

Guideway Type BOX Way

Spindle speed (rpm) 2,000

Max. No. of Tool (pcs) 10

FFG DMC DL 45

DL 45

Travel (X/Z) (mm) (inch) 350 x 4,530 (13.78″ x 60.24″)

Guideway Type BOX Way

Spindle speed (rpm) 2,000

Max. No. of Tool (pcs) 12

FFG DMC DL 55

DL 55

Travel (X/Z) (mm) (inch) 350 x 1,530 (13.78″ x 60.24″)

Guideway Type BOX Way

Spindle speed (rpm) 1,700

Max. No. of Tool (pcs) 12

FFG DMC DL 60L

DL 60L

Travel (X/Z) (mm) (inch) 470 x 3,270 (18.50″ x 128.74″)

Guideway Type BOX Way

Spindle speed (rpm) 1,400

Max. No. of Tool (pcs) 12

FFG DMC DL 22LMS

DL 22LMS

Travel (X/Z/B/Y) (mm) (inch) 470 x 3,270 (7.48″ x 21.65″ x 22.83″ x -)

Guideway Type (X/Z/B/Y) BOX Way

Main spindle speed (rpm) 1,400

Number of Tool (pcs) 12

FFG DMC DL 25SY

DL 22SY

Travel (X/Z/B/Y) (mm) (inch) 220 x 1,050 (8.66″ x 41.34″ x 37″ x ±2.17)

Guideway Type (X/Z/B/Y) BOX Way

Main spindle speed (rpm) 3,500

Number of Tool (pcs) 12

TRAK TC820SI

Hardened Box Ways on a Solid Casting provide increased rigidity, better damping, and less vibration for all purpose heavy duty cutting.

12-Station Bolt-On Turret for 0.75″ tooling with hydraulic locking system provides a reliable, precise interface between the machine, the tool and the work piece.

Coolant Through Turret efficiently dissipates chips and heat during machining. This greatly enhances cutting performance, accuracy, surface finish and tool life.

Manual Tailstock with Hydraulic Quill provides additional support for longer workpieces. Quill stroke of 4.13″ with MT4 taper.

4,000 RPM Spindle with 2.56″ Bar Capacity provides high axial thrust and generates minimal heat. It uses four P4 class angular bearings for optimal support and rigidity.

Tool Setting Arm and Probe with user-friendly interface for fast and reliable tool setup.

Direct Drive on X and Z Axes provide a rigid connection between the motor and the ballscrew for optimum servo control. This enhances accuracy and eliminates backlash.

Automatic Lubrication controlled by the CNC system monitors and distributes oil to the box ways and ballscrews to ensure all critical components are always lubricated with the correct amount of oil.

Standard Coolant System features a 20-gallon tank and pump providing coolant through tool @ 30 psi. High-pressure coolant option also available.

SIMOTICS M-1PH8 Asynchronous Induction Spindle Motor with 14.75 HP continuous — capable of handling extreme duty cycles and short rise times.

Chip Conveyor features an internal collection and side discharge system with a high rate of material removal. Chip cart is optional.

High Performance Servo Motors with excellent positioning accuracy.

Other Standard Features:

- Small footprint and generous 8.66″ maximum turned diameter and 20″ maximum turned length.

- Heavy Machine Tool Construction provides mass for rigidity and heavy cuts.

- Solid Casting for vibration absorption and rigidity.

- Precision Ground Ballscrews

- Guarding on All Axes to protect the castings, ballscrews and drivetrain systems.

- 7.88″ Hydraulic 3 Jaw Chuck for A2-6 spindle nose

- 787 IPM Feedrate on Z-Axis and 590 IPM Feedrate on X-Axis with aggressive acceleration and jerk control for ultra-fast positioning and reduced cycle times.

- Absolute Position Encoders to eliminate homing and enhance precision.

- Fine Chip Strainer has a metal screen with 1.7 mm openings to prevent large chips from clogging the coolant pumps.

- Large Single Front Door with large viewing window for easy access and integration with automation.

VISION WIDE SM Series

The structural analysis and optimization of the SM machine model stabilizes the structure of the fuselage and provides the best high dynamic rigidity when the machine moves at high speed.

High-precision positioning and emphasis on positioning accuracy provide the best choice for precision machining of auto parts, small car molds, mold bases, mechanical hardware parts and so on.

- Large table clamping area

- Optimized positioning accuracy

- Y axis increases machining stroke

- 15m / min high-speed cutting feed

- Structural design of machine tools for high-torque high-speed cutting applications

- Torque output of full tooth spindle 1,163Nm (15 / 18.5kW)

VISION WIDE SE Series

SE series, a 3-axis portal type CNC High Speed milling machine center released in 2017 , and it was designed particularly for mold processing, aluminum alloy machining and mass removal machining.

SE high speed machining center had a 50% improvement in productivity by excellent mechanism and structural performance.

- Spindle speed reaches 24,000 rpm

- 20 m/min of feed rate

- Precise contour accuracy

- Delicate surface roughness

- Positioning accuracy P 0.007mm

- Repeatability Ps 0.003 mm

- Aluminum alloy chips removal rate 5,000 cc/ min

VISION WIDE SF Series

SF series, the most popular bridge type CNC milling machining center of Vision Wide, is 3-axis linear way design with rapid traverse reaching 24 m / min and cutting feed rate reaching 10 m/ min. Suitable for fine components machining and mold cutting.

Its full casting structure provides long term accuracy stability, and ultra-wide column structure with big dimension surface provides the best rigid support of spindle and YZ axis.

Worth value, excellent manufacturing quality, and complete range of specification.

- Ultra-wide base of X axis with thick high rigidity table enhances table load capacity and ensures the best dynamic level accuracy.

- Large stepped design of Y axis makes guide ways close to beam and spindle which effectively increases rigidity of cutting load.

- Z axis 15m rapid traverse, high acceleration/deceleration performance to achieve contour accuracy of high speed mold machining.

- Spindle and thermal compensation function for environmental temperature change can be chosen to ensure the accuracy change within 0.02mm which influenced by environmental temperature change.

VISION WIDE NF Series

NF series, 3-axis bridge-type CNC milling machining center, is one of the most attractive products of Vision Wide, for its linear guideways and Z axis box way, wide-ranging Y travel from 2,300 mm to 3,900 mm, and much wider choices of X travel from 2,200 mm to 10,200 mm.

Positioning accuracy could reach ±0.005/300 mm (JIS B6333).

NF satisfies various demands in mold surface cutting, angles cutting, 3D mold cutting and precise contour finishing, and it also completes automatic 5-face machining with special designed accessories such as tool center point compensation, auto multi-angle head attachments and auto tool change system.

- High rigidity box base, best span work table guideways, and wider load dimension ensured best level dynamic accuracy.

- Cross-section square beam enabled the centroid of the head close to the beam center to ensure heavy cutting ability.

- Fully auto 5-face machining capacity

- Auto head change: 90º head / extension head / universal head

- AVertical and horizontal auto tool change for 90º head.

- A3-axis mechanical coordinates system

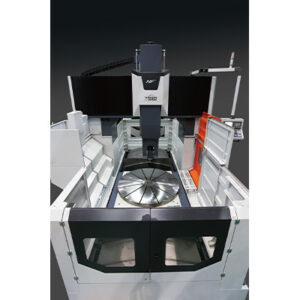

VISION WIDE NFT Series

NFT series inherits Vision Wide’s high structural rigidity product design. The addition of a rotary table makes it easier for the engineering, hydraulic, tire mold, turbine blade and all cylindrical workpiece machining.

VISION WIDE HF Series

HF series, the 3-axis bridge type CNC milling machining center, is one of the most proud products of Vision Wide which fulfills automatic 5-face machining with super rigidity structure and high positioning accuracy, and its X travel ranges from 4,200mm to 10,200mm, and Y travel ranges from 3,500mm to 4,700mm . HF satisfies demands in mold surface cutting, angles cutting, 3D mold cutting, and precise contour finishing

We developed tool center point compensation, auto multi-angle head attachment, and auto tool change system to complete auto 5-face machining.

- High rigidity box base, best span worktable guideways, and wider load dimension ensured best level dynamic accuracy.

- Cross-section square beam enabled the center of the head close to the beam center to ensure heavy cutting ability.

- Fully auto 5-face machining capacity

- Auto head change: 90º head / extension head / universal head

- AVertical and horizontal auto tool change for 90º head.

- A3-axis mechanical coordinates system

VISION WIDE HFM Series

HFM series is Vision Wide designed for ultra large workpieces machining, which fulfills automatic 5-face machining with super rigidity structure and high positioning accuracy, satisfies demands in heavy cutting ability, angles cutting , 3D mold cutting, and precise contour finishing.

We developed tool center point compensation, auto multi-angle head attachment, and auto tool change system to complete auto 5-face machining.

- Cross beam design with box-in-box structure can reduce deformation caused by Z-axis loaded on unilateral cross beam.

- The gravity center of head is located on the centerline of symmetric structure , the design can reduce the influence from ambient temperature.

- Head adopts hydrostatic transmission design which provides better rigidity, low friction and stability for large Z-axis travel machine.

- 1,500~2,000Nm Spindle Torque output.

VISION WIDE VB Series

VB series, a CNC milling double column/ bridge machining center, applied box guide ways to display Vision Wide’s delicate scrapping and traditional machinery techniques. VB equipped extraordinary heavy duty cutting ability that met cutting requirements for mold base and components. Meanwhile, there were auto heads attachments for mold surface machining.

- Three axes movement is fully supported by Harden box way with low friction.

- Box ways was heat treated to HRC 50 hardness, and was precisely hand scrapping, then assemble and tune to best accuracy to ensure smooth and precise feeding performance.

- Box-shape with ribs design , main casting structure parts are made of Meehanite grade casting iron with stress- relief heat treatment provide durable, rigid support of the machine.

- Large size Guide ways are designed with optimal span to carry the table, box-shape bed with strong V-shape enforced ribs allows heavy work piece load.

- The best center-line layout of spindle system, spindle is close to the Y box way reduce the unbalanced cutting moment and offset of thermal expansion to minimum.

VISION WIDE VF Series

VF series, classic CNC milling double column/ bridge machining center in Vision Wide product lines, applied box guide ways to display Vision Wide’s delicate scrapping and traditional machinery techniques. VF equipped extraordinary heavy duty cutting ability that met cutting requirements for mold base and components. Meanwhile, there were auto heads attachments for mold surface machining.

Unique design of sloping beam enabled the center of Z axis close to the beam, and s

- Three axes movement is fully supported by Harden box way with low friction.

- Box ways was heat treated to HRC 50 hardness, and was precisely hand scrapping, then assemble and tune to best accuracy to ensure smooth and precise feeding performance.

- Box-shape with ribs design , main casting structure parts are made of Meehanite grade casting iron with stress- relief heat treatment provide durable, rigid support of the machine.

- Large size Guide ways are designed with optimal span to carry the table, box-shape bed with strong V-shape enforced ribs allows heavy work piece load.

- The best center-line layout of spindle system, spindle is close to the Y box way reduce the unbalanced cutting moment and offset of thermal expansion to minimum.

FFG DMC DL 40V

DL 40V

Travel (X/Z) (mm) (inch) 200 x 350 (7.87″ x 13.78″)

Guideway Type BOX Way

Spindle speed (rpm) 4,000

Max. No. of Tool (pcs) 8

FFG DMC DL 40VTT

DL 40VTT

Travel (X/Z) (mm) (inch) 200 x 350 (7.87″ x 13.78″)

Guideway Type BOX Way

Spindle speed (rpm) 4,000

Max. No. of Tool (pcs) 8