| Model | VF-3000 | VF-4000 | VF-5000 | VF-3026 | VF-4026 | VF-5026 |

|---|---|---|---|---|---|---|

| X axis mm | 3,200 | 4,200 | 5,200 | 3,200 | 4,200 | 5,200 |

| Y axis mm | 2,300 | 2,300 | 2,300 | 2,600 | 2,600 | 2,600 |

| Z axis Box way mm | 920 / 1,020 (opt.) | 920 / 1,020 (opt.) | 920 / 1,020 (opt.) | 920 / 1,020 (opt.) | 920 / 1,020 (opt.) | 920 / 1,020 (opt.) |

| Dimension mm | 3,200 × 2,050 | 4,200 × 2,050 | 5,200 × 2,050 | 3,200 × 2,050 | 4,200 × 2,050 | 5,200 × 2,050 |

| Max. table load kg | 11,000 | 13,000 | 15,000 | 11,000 | 13,000 | 15,000 |

| Spindle motor (cont./30 min. rated) kW | 18.5/22 (22/26 opt.)(30/37 opt.) | 18.5/22 (22/26 opt.)(30/37 opt.) | 18.5/22 (22/26 opt.)(30/37 opt.) | 18.5/22 (22/26 opt.)(30/37 opt.) | 18.5/22 (22/26 opt.)(30/37 opt.) | 18.5/22 (22/26 opt.)(30/37 opt.) |

| Spindle speed (Box way) 2-step gear rpm | 4,000 / 6,000 (opt.) | 4,000 / 6,000 (opt.) | 4,000 / 6,000 (opt.) | 4,000 / 6,000 (opt.) | 4,000 / 6,000 (opt.) | 4,000 / 6,000 (opt.) |

| Spindle speed (Box way) Belt-driven rpm | 8,000 (opt.) / 10,001 (opt.) | 8,000 (opt.) / 10,001 (opt.) | 8,000 (opt.) / 10,001 (opt.) | 8,000 (opt.) / 10,000 (opt.) | 8,000 (opt.) / 10,000 (opt.) | 8,000 (opt.) / 10,000 (opt.) |

| Spindle taper | ISO 50 | ISO 50 | ISO 50 | ISO 50 | ISO 50 | ISO 50 |

| Cutting feed rate mm/min | 1-7,000 | 1-7,000 | 1-7,000 | 1-7,000 | 1-7,000 | 1-7,000 |

| Rapid traverse m/min | X/Y/Z:12 | X:10,Y/Z:12 | X:10,Y/Z:12 | X/Y/Z:12 | X:10,Y/Z:12 | X:10,Y/Z:12 |

| Positioning accuracy mm (Refer to JIS B6333) | ±0.005 / 300, ±0.015 Full travel | ±0.005 / 300, ±0.015 Full travel | ±0.005 / 300, ±0.015 Full travel | ±0.005 / 300, ±0.015 Full travel | ±0.005 / 300, ±0.015 Full travel | ±0.005 / 300, ±0.015 Full travel |

| Repeatability mm (Refer to JIS B6333) | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 |

| ATC capacity pcs | 40/60 (opt.) | 40/60 (opt.) | 40/60 (opt.) | 40/60 (opt.) | 40/60 (opt.) | 40/60 (opt.) |

| Machine gross weight kg | 37,100 | 43,400 | 48,400 | 40,100 | 46,400 | 51,400 |

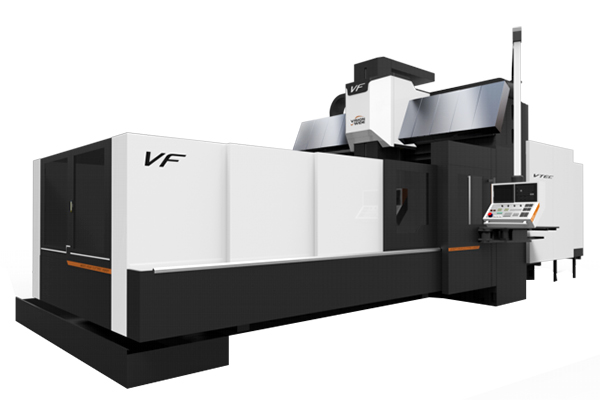

VISION WIDE VF Series

VF series, classic CNC milling double column/ bridge machining center in Vision Wide product lines, applied box guide ways to display Vision Wide’s delicate scrapping and traditional machinery techniques. VF equipped extraordinary heavy duty cutting ability that met cutting requirements for mold base and components. Meanwhile, there were auto heads attachments for mold surface machining.

Unique design of sloping beam enabled the center of Z axis close to the beam, and s

- Three axes movement is fully supported by Harden box way with low friction.

- Box ways was heat treated to HRC 50 hardness, and was precisely hand scrapping, then assemble and tune to best accuracy to ensure smooth and precise feeding performance.

- Box-shape with ribs design , main casting structure parts are made of Meehanite grade casting iron with stress- relief heat treatment provide durable, rigid support of the machine.

- Large size Guide ways are designed with optimal span to carry the table, box-shape bed with strong V-shape enforced ribs allows heavy work piece load.

- The best center-line layout of spindle system, spindle is close to the Y box way reduce the unbalanced cutting moment and offset of thermal expansion to minimum.

| Standard Accessory & Function | Optional Accessory & Function |

|---|---|

| 1. Fanuc 0i MF Controller | 1. 6,000 rpm 2-step gear spindle |

| 2. 4,000 rpm two-step gear spindle | 2. 8,000/10,000 rpm belt-driven spindle |

| 3. Spindle oil cooler | 3. Z-axis travel 1,020mm |

| 4. Twin hydraulic cylinders with pressured air assistance balancing system | 4. 200/300/400/500 mm higher column |

| 5. X-axis ball screw supporter ( X > 4m above) | 5. Interface preparation for coolant through spindle system |

| 6. Centralized auto lubrication system | 6. Coolant through spindle system 20/70 bar |

| 7. Independent lubrication oil collector | 7. Coolant through tool holder interface |

| 8. Ball screw cooling system | 8. Coolant through tool holder 5 bar /20 bar cutting fluid interface |

| 9. Air blast through spindle | 9. Oil skimmer |

| 10. Wash gun and pneumatic interface | 10. Oil mist cooling device |

| 11. Cutting fluid cooling system | 11. Spindle ring cutting coolant device ( for no head attachment) |

| 12. 40 tools magazine with arm type ATC | 12. 60 tools magazine with arm type ATC |

| 13. Enclosed splash guard (without roof) | 13. Enclosed splash guard with roof |

| 14. Swiveling arm type operation panel | 14. Chip auger on table side |

| 15. Screw type chip conveyor on table side | 15. Chip cart |

| 16. Caterpillar type chip conveyer | 16. Air conditioner for electrical cabinet |

| 17. Heat exchanger for electrical cabinet | 17. XYZ-axis linear scale feedback |

| 18. Working lamp | 18. 3-axis independent manual pulse generator |

| 19. Operation cycle finish and alarm light | 19. Sub table |

| 20. Movable manual pulse generator (MPG) | 20. Rotary table |

| 21. Footswitch for tool clamping | 21. Interface preparation for rotary table |

| 22. RS232 and RJ45 interface | 22. Z-axis retract function at power failure |

| 23. XYZ-axis absolute pulse coder feedback | 23. Anti-collision and machining simulation software |

| 24. XYZ-axis travel hard limits protection | 24. Remote monitoring software-Professional (Not available for Siemens controller) |

| 25. Spindle cutting load software protection | 25. Automatic tool length measurement |

| 26. Remote monitoring software-Standard (Not available for Siemens controller) | 26. Automatic workpiece measurement |

| 27. Auto power off | 27. Transformer |

| 28. Vision Wide FX graphical user interface (Fanuc only) | 28. Auto warm up |

| 29. Foundation pads and bolts kits | |

| 30. Adjustment tool and tool kits (without roof) | |

| 31. Technical manuals (operation, maintenance manual and circuit diagram) |