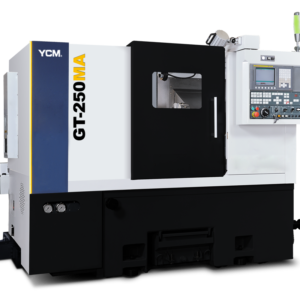

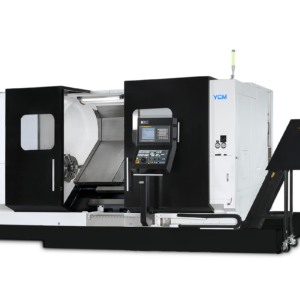

YCM GT250MA

- The box-type design offers a ultra-wide base structure, high quality MEEHANITE® castings, oversize hardened & ground boxed ways to ensure the best machining performance by eliminating structural distortion and deformation under heavy machining conditions.

- The tailstock is supported by hardened and ground boxed ways that is structurally one-piece with the machine base, which ensures the best structural rigidity.

- The oversize quill supports heavy workpieces while maintaining machining accuracy.

- Optional live quill is ideal for high-speed, high production environment.

- Automatic Tool Length Measurement (opt.)

- Automatic Bar-feeder System (opt.)

- Automatic Parts Catcher (opt.) and Transfer System (opt.)

- Oversize hardened and ground box ways, ballscrew and bearings are essential requirements for enhancing the axial and radial cutting rigidity.

- High torque spindle motor provides the necessary power for roughing operation on tough material at low spindle speed.

- High quality chuck with powerful hydraulic system ensures machining rigidity and accuraacy.

- Pressure sensors are added to hydraulic system for monitoring clamping force of chuck, assuring the proper clamping of heavy parts.

- All spindles are strictly assembled in temperature controlled room, and proven through rigorous run-in test to assure the highest quality and reliability.The unique quill-type spindle cartridge designed for easy maintenance and repair if necessary.

- Oversize dual roller spindle bearings are used in both front and rear of the spindle to provide optimal spindle rigidity that is capable of handling 10mm cutting depth on hard material.

- The spindle headstock is symmetrically designed with radial configuration for the best heat reduction.

- Reinforced ventilation is located throughout the spindle head to minimize thermal growth.

- Effective exhaust fans are installed on the spindle headstock to remove the heat generated from long running hours.

- High performance piston pump and radiation system are added to control the temperature of hydraulic oil, which minimize the thermal impact of hydraulic system.

- Isolated coolant tanks eliminate the effect of high coolant temperature after long running hours, which reduces structural deformation.

- The spindle motor sits outside of the machine base to isolate the heat generated from spindle motor after long operations.

- Low heat generated work lamp is installed to minimize temperature impact.

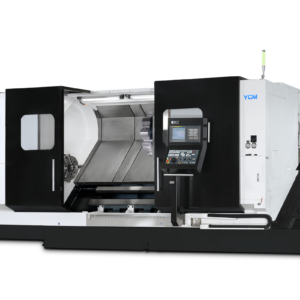

YCM GT300B

- The box-type design offers a ultra-wide base structure, high quality MEEHANITE® castings, oversize hardened & ground boxed ways to ensure the best machining performance by eliminating structural distortion and deformation under heavy machining conditions.

- The tailstock is supported by hardened and ground boxed ways that is structurally one-piece with the machine base, which ensures the best structural rigidity.

- The oversize quill supports heavy workpieces while maintaining machining accuracy.

- Optional live quill is ideal for high-speed, high production environment.

- Automatic Tool Length Measurement (opt.)

- Automatic Bar-feeder System (opt.)

- Automatic Parts Catcher (opt.) and Transfer System (opt.)

- Oversize hardened and ground box ways, ballscrew and bearings are essential requirements for enhancing the axial and radial cutting rigidity.

- High torque spindle motor provides the necessary power for roughing operation on tough material at low spindle speed.

- High quality chuck with powerful hydraulic system ensures machining rigidity and accuraacy.

- Pressure sensors are added to hydraulic system for monitoring clamping force of chuck, assuring the proper clamping of heavy parts.

- All spindles are strictly assembled in temperature controlled room, and proven through rigorous run-in test to assure the highest quality and reliability.The unique quill-type spindle cartridge designed for easy maintenance and repair if necessary.

- The spindle headstock is symmetrically designed with radial configuration for the best heat reduction.

- Reinforced ventilation is located throughout the spindle head to minimize thermal growth.

- Effective exhaust fans are installed on the spindle headstock to remove the heat generated from long running hours.

- High performance piston pump and radiation system are added to control the temperature of hydraulic oil, which minimize the thermal impact of hydraulic system.

- Isolated coolant tanks eliminate the effect of high coolant temperature after long running hours, which reduces structural deformation.

- The spindle motor sits outside of the machine base to isolate the heat generated from spindle motor after long operations.

- Low heat generated work lamp is installed to minimize temperature impact.

YCM GT300MA

- The box-type design offers a ultra-wide base structure, high quality MEEHANITE® castings, oversize hardened & ground boxed ways to ensure the best machining performance by eliminating structural distortion and deformation under heavy machining conditions.

- The tailstock is supported by hardened and ground boxed ways that is structurally one-piece with the machine base, which ensures the best structural rigidity.

- The oversize quill supports heavy workpieces while maintaining machining accuracy.

- Optional live quill is ideal for high-speed, high production environment.

- Automatic Tool Length Measurement (opt.)

- Automatic Bar-feeder System (opt.)

- Automatic Parts Catcher (opt.) and Transfer System (opt.)

- Oversize hardened and ground box ways, ballscrew and bearings are essential requirements for enhancing the axial and radial cutting rigidity.

- High torque spindle motor provides the necessary power for roughing operation on tough material at low spindle speed.

- High quality chuck with powerful hydraulic system ensures machining rigidity and accuraacy.

- Pressure sensors are added to hydraulic system for monitoring clamping force of chuck, assuring the proper clamping of heavy parts.

- All spindles are strictly assembled in temperature controlled room, and proven through rigorous run-in test to assure the highest quality and reliability.The unique quill-type spindle cartridge designed for easy maintenance and repair if necessary.

- The spindle headstock is symmetrically designed with radial configuration for the best heat reduction.

- Reinforced ventilation is located throughout the spindle head to minimize thermal growth.

- Effective exhaust fans are installed on the spindle headstock to remove the heat generated from long running hours.

- High performance piston pump and radiation system are added to control the temperature of hydraulic oil, which minimize the thermal impact of hydraulic system.

- Isolated coolant tanks eliminate the effect of high coolant temperature after long running hours, which reduces structural deformation.

- The spindle motor sits outside of the machine base to isolate the heat generated from spindle motor after long operations.

- Low heat generated work lamp is installed to minimize temperature impact.

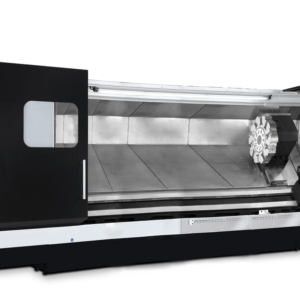

YCM GT300LMB

- The box-type design offers a ultra-wide base structure, high quality MEEHANITE® castings, oversize hardened & ground boxed ways to ensure the best machining performance by eliminating structural distortion and deformation under heavy machining conditions.

- The tailstock is supported by hardened and ground boxed ways that is structurally one-piece with the machine base, which ensures the best structural rigidity.

- The oversize quill supports heavy workpieces while maintaining machining accuracy.

- Optional live quill is ideal for high-speed, high production environment.

- Automatic Tool Length Measurement (opt.)

- Automatic Bar-feeder System (opt.)

- Automatic Parts Catcher (opt.) and Transfer System (opt.)

- Oversize hardened and ground box ways, ballscrew and bearings are essential requirements for enhancing the axial and radial cutting rigidity.

- High torque spindle motor provides the necessary power for roughing operation on tough material at low spindle speed.

- High quality chuck with powerful hydraulic system ensures machining rigidity and accuraacy.

- Pressure sensors are added to hydraulic system for monitoring clamping force of chuck, assuring the proper clamping of heavy parts.

- All spindles are strictly assembled in temperature controlled room, and proven through rigorous run-in test to assure the highest quality and reliability.The unique quill-type spindle cartridge designed for easy maintenance and repair if necessary.

- The spindle headstock is symmetrically designed with radial configuration for the best heat reduction.

- Reinforced ventilation is located throughout the spindle head to minimize thermal growth.

- Effective exhaust fans are installed on the spindle headstock to remove the heat generated from long running hours.

- High performance piston pump and radiation system are added to control the temperature of hydraulic oil, which minimize the thermal impact of hydraulic system.

- Isolated coolant tanks eliminate the effect of high coolant temperature after long running hours, which reduces structural deformation.

- The spindle motor sits outside of the machine base to isolate the heat generated from spindle motor after long operations.

- Low heat generated work lamp is installed to minimize temperature impact.

YCM NT2500SY

- 30° One-piece Slanted Bed Design: Extends the space for chips removal.

- Highly Rigid Bridge Type Base:Effectively absorbs vibration and reduces structural deformation.

- Enlarged Box Guideway Width:The oversized guideways are treated through induction hardening process and precision ground to achieve optimal rigidity, accuracy, and longevity.

- Fast & Reliable Motorized Turret:Servo-driven design achieves fast tool changing time and reliable indexing.

- The built-in spindle design alleviates tension, slip and vibration generated by traditional belt-driven spindle design. With large diameter bearing, it greatly improves rigidity.

- The built-in spindle is circulated cooled and controls temperature growth with oil cooling system, so as to reduce thermal deformation and improve spindle speed.

- The spindle utilizes large diameter bearing that improves rigidity. Combining bearing characteristics and radial, axial and synthetic loads that ensures the spindle perform high precision turning and heavy duty cutting at low speed.

- C-axis index: 0.001°.

- Y plus C-axis integrates mill/turn process and fulfills numerous complex requirements which can do more than general lathes.

- Direct drive motors on X/Y/Z/B-axis reduce backlash and vibration problems and achieve accurate positioning.

- 12 tools capacity. All stations are available for live tools.

- The radial power turret combines turning and milling capacities that reduces turret interference.

- The turrets are servo motor driven with hydraulic clamping design for saving tool change time.

- With highly accurate big diameter coupling, the higher positioning accuracy and repeatability accuracy they will be.

YCM TC16LA

- 6″ (Hole through Draw Bar ø52mm); 8″ (Hole through Draw Bar ø66mm)

- With low resistance and low friction, theLinear Guideway Design on X/Z Axis prolongs machine life.

- One-piece 45° Slant bed design extends the space for removing chips.

- MEEHANITE® casting with high damping capacity

- Quick and reliable servo-driven turret is hydralic clamping

- Extra large and high precision clutch provides high positioning and repeatability accuracy.

- Diverse choices of tailstock and turning length

- Diverse choices of tailstock and turning length

- High efficiency and low power loss plunger pump adopted

- Large diameter and high precision NN series roller bearings, equipped with angular contact ball bearings, provides the best radial and axial rigidity during machining.

- Symmetric head design dissipates heat, and reduces thermal deformation.

- Easy to adjust and repair.

- With low resistance and low friction, the linear guideway design on X/Z axis achieves flawless positioning accuracy.

- The axial pretension design on ball screws reduces thermal displacement.

- Reduce manual loading/unloading time and achieve 24-hour production, improving the factory utilization.

- Save labor cost, improve productivity and lower defection rate.

- Reduce changeover time to meet the demand of low volume production of diversified parts.

- Flexible modular system and easy to be installed based on various product line.

- 45°one-piece slant bed design extends chips removal space.

- The independent coolant tank isolates the base from heat exposure.

- A special design of the coolant tank prevents the chips from flowing into the machine.

- The design of main/sub coolant tank simplifies the cleaning of chip conveyor.

- The filter and sub coolant tank can be drawn out separately for easy maintenance.

YCM TC16LB

- 45°one-piece slant bed design extends chips removal space.

- The independent coolant tank isolates the base from heat exposure.

- A special design of the coolant tank prevents the chips from flowing into the machine.

- The design of main/sub coolant tank simplifies the cleaning of chip conveyor.

- The filter and sub coolant tank can be drawn out separately for easy maintenance.

- 6″ (Hole through Draw Bar ø52mm); 8″ (Hole through Draw Bar ø66mm)

- With low resistance and low friction, the Linear Guideway Design on X/Z Axis prolongs machine life.

- One-piece 45° Slant bed design extends the space for removing chips.

- MEEHANITE® casting with high damping capacity

- Quick and reliable servo-driven turret is hydraulic clamping

- Extra large and high precision clutch provides high positioning and repeatability accuracy.

- Diverse choices of tailstock and turning length

- Diverse choices of tailstock and turning length

- High efficiency and low power loss plunger pump adopted

- Large diameter and high precision NN series roller bearings, equipped with angular contact ball bearings, provides the best radial and axial rigidity during machining.

- Symmetric head design dissipates heat, and reduces thermal deformation.

- Easy to adjust and repair.

- With low resistance and low friction, the linear guideway design on X/Z axis achieves flawless positioning accuracy.

- The axial pretension design on ball screws reduces thermal displacement.

- Reduce manual loading/unloading time and achieve 24-hour production, improving the factory utilization.

- Save labor cost, improve productivity and lower defection rate.

- Reduce changeover time to meet the demand of low volume production of diversified parts.

- Flexible modular system and easy to be installed based on various product line.

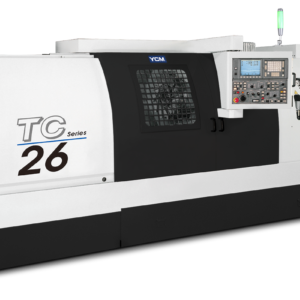

YCM TC26

- The 12-station turret index is done by absolute detection to reduce tool selection mistake.

- The powerful turret with large diameter curvic coupling offers high precision and high rigidity in cutting performance.

- The spindle is equipped with high precision angular ball bearing and NN series bearing that provides high precision and rigidity working condition.

- The inner diameter of the bearing is ø120mm ø4.72″, and ø88mm ø3.46″ of the spindle through hole. ø78mm ø3.07″ of the drawbar through hole adapts large diameter bar stock jobs.

- The powerful spindle with built-in gears provides various speed transmissions. The max. output of torque reaches 74.5kgf-m 539 lb-ft, with 4,000rpm max. spindle speed.

- Material Removal Efficiency: 410cm3/min.

- Insert Depth: 8mm 0.31″

- Extremely Rigid One-piece 45° Slanted Bed Design

- Using “M” code commands the quill stroke of the programmable tailstock can be hooked with a hydraulic hook to the saddle carriage and slide along the Z-axis stroke.

- X/Z-axis guideways are well hardened and ground with Turcite-B to reduce the friction and offer utmost rigidity in cutting. The rapid feedrate of X/Z-axis is 15/20 m/min. 591/787ipm

- Hydraulic gauges, control values of chuck and tail stock, and the central lubrication system are installed at the front side; for easy adjustment and maintenance.

- This machine is equipped with high precision ball screws and connected with motor directly. The fixing design supports both ends; the design of pre-tensioned ball screws provides high rigidity, high precision, and low heat effect.

- The machine with auto-lubrication design ensures the accuracy throughout its life time.

- The slide ways of X/Z-axis and ball screws are lubricated. Built-in alarm will occurred when the lubrication oil is insufficient.

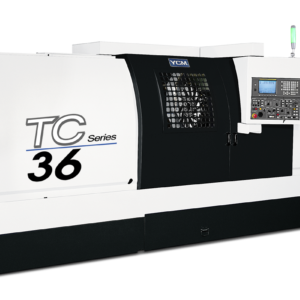

YCM TC36

- The 12-station turret index is done by absolute detection, and no tool selection mistake is caused.

- The powerful turret of large diameter curvic coupling offers high precision and high rigidity in cutting performance.

- The spindle is equipped with high precision angular ball bearing and NN series bearing witch provides high precision and rigidity working condition.

- The inner diameter of the bearing is ø150mm ø5.91″, and ø105mm ø4.13″ of the spindle through hole. ø93mm ø3.66″ of the drawbar through hole adapts large diameter bar stock jobs.

- The powerful spindle with built-in gears provides various speed transmissions. The max. output of torque reaches 140kgf-m 1,013 lb-ft, with max. spindle speed of 2,500rpm.

- This machine is equipped with high precision ball screws and connected with motor directly. The fixing design supports both ends; the design of pre-tensioned ball screws provides high rigidity, high precision, and low heat effect.

- The stand alone oil tank ensures the machining precision will not be affected by heat. It is also convenient and efficient for cleaning and maintaining the oil tank.

- Hydraulic gauges, control values of chuck and tail stock, and the central lubrication system are located at the front side for easy operation and maintenance.

- Using “M” code commands the quill stroke of the programmable tailstock can be hooked with a hydraulic hook to the saddle carriage and slide along the Z-axis stroke. Tailstock with live quill is standard.

- From the window of the safety guard, operator can see through the engaged job, and shield from the cutting chips and coolant mist.

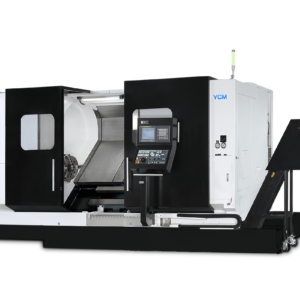

YCM TC46/1000

- With years of experience, combining advanced technology and facilities, YCM has successfully developed highly rigid CNC Turning Centers, TC-46. TC-46 is specially designed for producing large workpieces with high accuracy, suitable for valve and hydraulic components, shipbuilding, automobiles, construction and energy industries.

- Equipped with A2-11 spindle nose and 15″ chuck. (18″/21″/24″ chick or customized fixture is optional.)

- The chuck is operated by pedal switch for more safety and user-friendly.

- The clamping pressure can be adjusted by workpiece shape and material.

- Extra large bearing with excellent rigidity for heavy duty cutting capability.

- The extra large front bearing internal diameter is ø180 mm to ensure the heavy duty cutting capability.

- hole through spindle diameter is ø130 mm.

- hole through draw bar is ø117 mm.

- A2-15 spindle of Big bore hole for flexible chuck 15″/18″/21″/24″, hole through Spindle ø182 mm ø7.17″.

- MEEHANITE® casting frame through FEM analysis for one piece torque tube and 45 degree slant bed ensures the best rigidity and eliminates casting distortion.

- Z-axis design with an extra wide distance o f 620mm between guideways offers the highest rigidity.

- The box way base of 950mm is suitable for heavy duty machining and powerful chip removal.

- The slide ways of X/Z-axis and ball screws are lubricated. Built-in alarm will be occurred when the lubrication oil is insufficient.

- Automatic Tool Pre-setter Reduces Setup Time (Opt.)

- Optional automatic tool pre-setter reduces setup time by minimizing skim cuts and entering tool offsets.

- The hydraulic balance cylinder on X-axis ensures the smoothest axial movement and brake system prevents the turret from dropping when the power is suddenly off.

- With the double nuts design, the ball screws on the X/Z-axis provide the highest rigidity.

- The optional safety clutch will disassemble the ball screw from motor to protect the ball screw during a crash.

- With slanted design and superb chip removal space under the spindle, it is more easier to clean chips.

- High pressure coolant is supplied for optimal chip removal.

- Shower coolant from the roof removes the chips from the chuck and telescopic guideway cover. (opt.)

- MT-5 fixed quill with live center is standard, high rigidity rotary quill with dead center is optional.

- Tail stock using dual cylinder to clamp the guideways for prevent tail stock skid during machining. Using hydraulic connect bar to link the tail stock and carriage during tail stock positioning to save effort and time.

- Equipped with large 10T (12T, opt.) servo driven turret that features fast turret indexing (0.9 sec.) and machining versatility.

- The large diameter of 3-piece curvic coupling design offers super rigid clamping force of 9,050kgf-m to ensure heavy cutting and long-term accuracy.

- Powerful 4 speed gear-head spindle is suitable for heavy duty machining requirements

- Oil-cooled chiller for excellent thermal stability

YCM TC46/1650

- With years of experience, combining advanced technology and facilities, YCM has successfully developed highly rigid CNC Turning Centers, TC-46. TC-46 is specially designed for producing large workpieces with high accuracy, suitable for valve and hydraulic components, shipbuilding, automobiles, construction and energy industries.

- Equipped with A2-11 spindle nose and 15″ chuck. (18″/21″/24″ chick or customized fixture is optional.)

- The chuck is operated by pedal switch for more safety and user-friendly.

- The clamping pressure can be adjusted by workpiece shape and material.

- Extra large bearing with excellent rigidity for heavy duty cutting capability.

- The extra large front bearing internal diameter is ø180 mm to ensure the heavy duty cutting capability.

- hole through spindle diameter is ø130 mm.

- hole through draw bar is ø117 mm.

- A2-15 spindle of Big bore hole for flexible chuck 15″/18″/21″/24″, hole through Spindle ø182 mm ø7.17″.

- MEEHANITE® casting frame through FEM analysis for one piece torque tube and 45 degree slant bed ensures the best rigidity and eliminates casting distortion.

- Z-axis design with an extra wide distance of 620mm between guideways offers the highest rigidity.

- The box way base of 950mm is suitable for heavy duty machining and powerful chip removal.

- The slide ways of X/Z-axis and ball screws are lubricated. Built-in alarm will be occurred when the lubrication oil is insufficient.

- Optional automatic tool pre-setter reduces setup time by minimizing skim cuts and entering tool offsets.

- Automatic Tool Pre-setter Reduces Setup Time (Opt.)

- The Smoothest X-axis Movement and Prevents Turret Drop

- The hydraulic balance cylinder on X-axis ensures the smoothest axial movement and brake system prevents the turret from dropping when the power is suddenly off.

- With the double nuts design, the ball screws on the X/Z-axis provide the highest rigidity.

- The optional safety clutch will disassemble the ball screw from motor to protect the ball screw during a crash.

- With slanted design and superb chip removal space under the spindle, it is more easier to clean chips.

- High pressure coolant is supplied for optimal chip removal.

- Shower coolant from the roof removes the chips from the chuck and telescopic guideway cover. (opt.)

- MT-5 fixed quill with live center is standard, high rigidity rotary quill with dead center is optional.

- Tail stock using dual cylinder to clamp the guideways for prevent tail stock skid during machining. Using hydraulic connect bar to link the tail stock and carriage during tail stock positioning to save effort and time.

- Equipped with large 10T (12T, opt.) servo driven turret that features fast turret indexing (0.9 sec.) and machining versatility.

- The large diameter of 3-piece curvic coupling design offers super rigid clamping force of 9,050kgf-m to ensure heavy cutting and long-term accuracy.

- Powerful 4 speed gear-head spindle is suitable for heavy duty machining requirements

- Oil-cooled chiller for excellent thermal stability

YCM TC46/2300

- With years of experience, combining advanced technology and facilities, YCM has successfully developed highly rigid CNC Turning Centers, TC-46. TC-46 is specially designed for producing large workpieces with high accuracy, suitable for valve and hydraulic components, shipbuilding, automobiles, construction and energy industries.

- Equipped with A2-11 spindle nose and 15″ chuck. (18″/21″/24″ chick or customized fixture is optional.)

- The chuck is operated by pedal switch for more safety and user-friendly.

- The clamping pressure can be adjusted by workpiece shape and material.

- Extra large bearing with excellent rigidity for heavy duty cutting capability.

- The extra large front bearing internal diameter is ø180 mm to ensure the heavy duty cutting capability.

- hole through spindle diameter is ø130 mm.

- hole through draw bar is ø117 mm.

- A2-15 spindle of Big bore hole for flexible chuck 15″/18″/21″/24″, hole through Spindle ø182 mm ø7.17″.

- MEEHANITE® casting frame through FEM analysis for one piece torque tube and 45 degree slant bed ensures the best rigidity and eliminates casting distortion.

- Z-axis design with an extra wide distance of 620mm between guideways offers the highest rigidity.

- The box way base of 950mm is suitable for heavy duty machining and powerful chip removal.

- The slide ways of X/Z-axis and ball screws are lubricated. Built-in alarm will be occurred when the lubrication oil is insufficient.

- Optional automatic tool pre-setter reduces setup time by minimizing skim cuts and entering tool offsets.

- The hydraulic balance cylinder on X-axis ensures the smoothest axial movement and brake system prevents the turret from dropping when the power is suddenly off.

- With the double nuts design, the ball screws on the X/Z-axis provide the highest rigidity.

- The optional safety clutch will disassemble the ball screw from motor to protect the ball screw during a crash.

- With slanted design and superb chip removal space under the spindle, it is more easier to clean chips.

- High pressure coolant is supplied for optimal chip removal.

- Shower coolant from the roof removes the chips from the chuck and telescopic guideway cover. (opt.)

- MT-5 fixed quill with live center is standard, high rigidity rotary quill with dead center is optional.

- Tail stock using dual cylinder to clamp the guideways for prevent tail stock skid during machining. Using hydraulic connect bar to link the tail stock and carriage during tail stock positioning to save effort and time.

- Equipped with large 10T (12T, opt.) servo driven turret that features fast turret indexing (0.9 sec.) and machining versatility.

- The large diameter of 3-piece curvic coupling design offers super rigid clamping force of 9,050kgf-m to ensure heavy cutting and long-term accuracy.

- Powerful 4 speed gear-head spindle is suitable for heavy duty machining requirements

- Oil-cooled chiller for excellent thermal stability

YCM TC46/3200

- With years of experience, combining advanced technology and facilities, YCM has successfully developed highly rigid CNC Turning Centers, TC-46. TC-46 is specially designed for producing large workpieces with high accuracy, suitable for valve and hydraulic components, shipbuilding, automobiles, construction and energy industries.

- Equipped with A2-11 spindle nose and 15″ chuck. (18″/21″/24″ chick or customized fixture is optional.)

- The chuck is operated by pedal switch for more safety and user-friendly.

- The clamping pressure can be adjusted by workpiece shape and material.

- Extra large bearing with excellent rigidity for heavy duty cutting capability.

- The extra large front bearing internal diameter is ø180 mm to ensure the heavy duty cutting capability.

- hole through spindle diameter is ø130 mm.

- hole through draw bar is ø117 mm.

- A2-15 spindle of Big bore hole for flexible chuck 15″/18″/21″/24″, hole through Spindle ø182 mm ø7.17″.

- MEEHANITE® casting frame through FEM analysis for one piece torque tube and 45 degree slant bed ensures the best rigidity and eliminates casting distortion.

- Z-axis design with an extra wide distance of 620mm between guideways offers the highest rigidity.

- The box way base of 950mm is suitable for heavy duty machining and powerful chip removal.

- The slide ways of X/Z-axis and ball screws are lubricated. Built-in alarm will be occurred when the lubrication oil is insufficient.

- Optional automatic tool pre-setter reduces setup time by minimizing skim cuts and entering tool offsets.

- The hydraulic balance cylinder on X-axis ensures the smoothest axial movement and brake system prevents the turret from dropping when the power is suddenly off.

- With the double nuts design, the ball screws on the X/Z-axis provide the highest rigidity.

- The optional safety clutch will disassemble the ball screw from motor to protect the ball screw during a crash.

- With slanted design and superb chip removal space under the spindle, it is more easier to clean chips.

- High pressure coolant is supplied for optimal chip removal.

- Shower coolant from the roof removes the chips from the chuck and telescopic guideway cover. (opt.)

- MT-5 fixed quill with live center is standard, high rigidity rotary quill with dead center is optional.

- Tail stock using dual cylinder to clamp the guideways for prevent tail stock skid during machining. Using hydraulic connect bar to link the tail stock and carriage during tail stock positioning to save effort and time.

- Equipped with large 10T (12T, opt.) servo driven turret that features fast turret indexing (0.9 sec.) and machining versatility.

- The large diameter of 3-piece curvic coupling design offers super rigid clamping force of 9,050kgf-m to ensure heavy cutting and long-term accuracy.

- Powerful 4 speed gear-head spindle is suitable for heavy duty machining requirements

- Oil-cooled chiller for excellent thermal stability

YCM TC46M/3200

- With years of experience, combining advanced technology and facilities, YCM has successfully developed highly rigid CNC Turning Centers, TC-46M. TC-46M is specially designed for producing large workpieces with high accuracy, suitable for valve and hydraulic components, shipbuilding, automobiles, construction and energy industries. What’s more, TC-46M is equipped with C-axis and motorized turret that provides a wide range of complex milling functions.

- Equipped with A2-11 spindle nose and 15″ chuck. (18″/21″/24″ chick or customized fixture is optional.)

- The chuck is operated by pedal switch for more safety and user-friendly.

- The clamping pressure can be adjusted by workpiece shape and material.

- Extra large bearing with excellent rigidity for heavy duty cutting capability.

- The extra large front bearing internal diameter is ø180 mm to ensure the heavy duty cutting capability.

- hole through spindle diameter is ø130 mm.

- hole through draw bar is ø117 mm.

- A2-15 spindle of Big bore hole for flexible chuck 15″/18″/21″/24″, hole through Spindle ø182 mm ø7.17″.

- MEEHANITE® casting frame through FEM analysis for one piece torque tube and 45 degree slant bed ensures the best rigidity and eliminates casting distortion.

- Z-axis design with an extra wide distance of 620mm between guideways offers the highest rigidity.

- The box way base of 950mm is suitable for heavy duty machining and powerful chip removal.

- The slide ways of X/Z-axis and ball screws are lubricated. Built-in alarm will be occurred when the lubrication oil is insufficient.

- Optional automatic tool pre-setter reduces setup time by minimizing skim cuts and entering tool offsets.

- Automatic Tool Pre-setter Reduces Setup Time (Opt.)

- The Smoothest X-axis Movement and Prevents Turret Drop

- The hydraulic balance cylinder on X-axis ensures the smoothest axial movement and brake system prevents the turret from dropping when the power is suddenly off.

- With the double nuts design, the ball screws on the X/Z-axis provide the highest rigidity.

- The optional safety clutch will disassemble the ball screw from motor to protect the ball screw during a crash.

- With slanted design and superb chip removal space under the spindle, it is more easier to clean chips.

- High pressure coolant is supplied for optimal chip removal.

- Shower coolant from the roof removes the chips from the chuck and telescopic guideway cover. (opt.)

- MT-5 fixed quill with live center is standard, high rigidity rotary quill with dead center is optional.

- Tail stock using dual cylinder to clamp the guideways for prevent tail stock skid during machining. Using hydraulic connect bar to link the tail stock and carriage during tail stock positioning to save effort and time.

- 12 tools capacity with BMT 85 tooling system.

- live tool power 15/18.5/22 kW 20/25/30 HP with Max. speed 3,000 rpm.

- Servo drive turret for high speed index.

- Hydraulic clamping turret with 3-piece large clutch for heavy duty cutting.

- Spindle quill /Gearbox with oil-cooling system for excellent thermal stability.

- Spindle motor power 30/37 kW 40/50 HP with 2 speed gear box.

- torque380 kgf-m

- C-axis with rotary encoder for high positioning 0.001 degree to provide excellent milling accuracy.

EXCETEK ED600C

Superior Erosion Function

EXCETEK of EDM create all by oneself MOSFET sparking circuit, with less electrode wear and fast erosion speed, can achieve mirror erosion with smooth surface roughness easy for polish.

Stable Generator with performance

Front and back separate double heat flow system, hot component and cold circuit separate, electronic component. adequately heat sink to improve generator working stable, nearly zero maintenance.

Simple Maintenance

EXCETEK EDM Generator use front and back assembly module design, function of circuit indicate clear, each circuit have fuse protection, easy for check maintenance and exchange PCB, provide user simple easy and speedy service quality.

Perfect of after sale service quality

EXCETEK of EDM provide full range of after sales service system, include Operation-Training-Maintenance-Application, According vanguard of professional management technology, to provide service quality and customer fear of disturbance in the rear after sales service support.