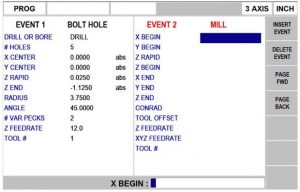

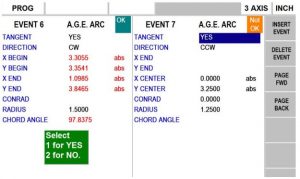

Auto Geometry Engine The Auto Geometry Engine (A.G.E.) is powerful software that automatically fills in missing print dimensions as you program. It is CAD capability embedded into CNC programming. Tool Path Graphics Profiles and Pockets Networking Spreadsheet Editing Advanced File Management Run-Time Clock

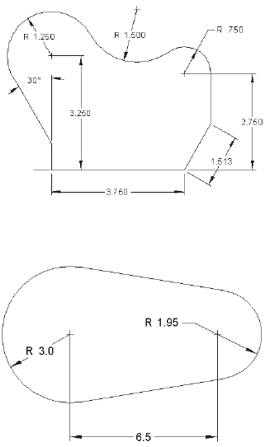

With A.G.E. you can make easy work out of programming incomplete prints or part sketches like the ones below. The A.G.E. doesn't take more time to use, it works automatically as you program.

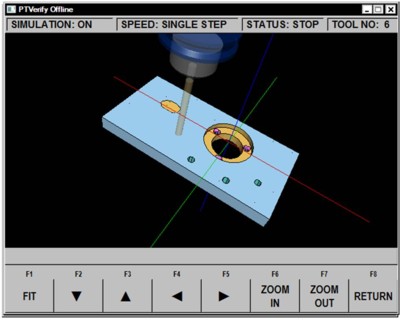

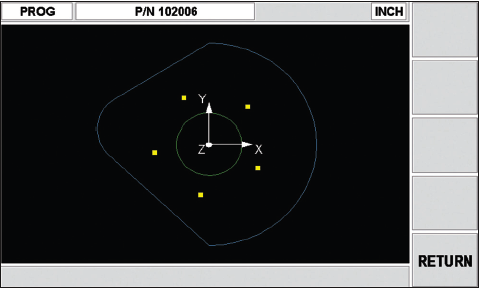

The ProtoTRAK relieves you from the chore of programming the tool path, but you will still be interested in seeing where the control is planning to move the tool. Colors, error messages and selectable views make it easy to check your program before you machine.

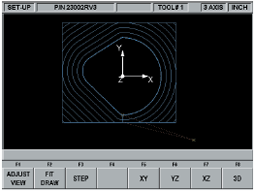

Programming pockets and profiles of all shapes is a breeze with powerful canned cycles.

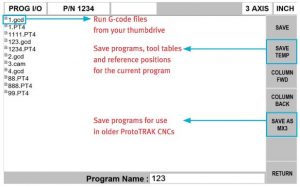

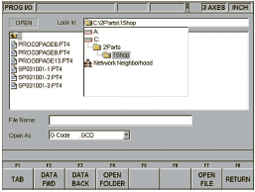

The ProtoTRAK may be networked with other ProtoTRAKs or with a server. This allows you to file, share or back-up programs right from your machine. Centralized file management helps assure revision control. Efficient file-sharing allows collaboration without time spent communicating between departments.

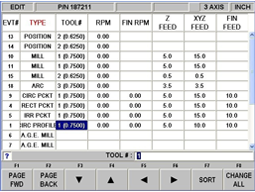

View data for your whole program all at once. Sort and make changes to whole groups of events with one press of a button. This is much more convenient than either moving through your program one event at a time or picking through a long list of G Codes.

The ProtoTRAK borrows the Windows® functionality and adds a couple of clever twists. File management is enhanced by the ability to access different drives, copy and rename files and look at the part graphics before opening the file. Backing up part programs is easy with the automatic back up routine.

In the run mode, the ProtoTRAK will display the time remaining until the next time the control is programmed to stop for a tool change. You know how long it will be before the job will need attention from you.

Retrofit EMX, KMX, SMX Kits

A great productivity investment

The more frugal you are, the more painful it should be to watch your people spend their time unproductively. The cost of the ProtoTRAK CNC is trivial when compared to the cost of the person standing in front of the machine. If you are going to keep and use the machine, retrofit it.

Even a machine that has some wear can be a good candidate for a retrofit. Ballscrews will be installed in the table and saddle and electronic machine tool error calibration and backlash compensation routines help maintain accuracy. If the head is in good condition, you probably have a useful machine.

We only retrofit small knee mills and our expertise is honed by twenty years’ experience and over 15,000 successful retrofits. The retrofit kit includes everything: motors, CNC, hardware, ballscrews, fasteners, even the cable ties. It is installed in your shop in about a day by a factory-trained technician. Custom kits for dozens of machines are available in either two or three-axis CNC.

You shouldn’t stop investing in productivity until all your machinists are working as efficiently as possible. Retrofitting can be a cost-effective way for you to reach that goal.

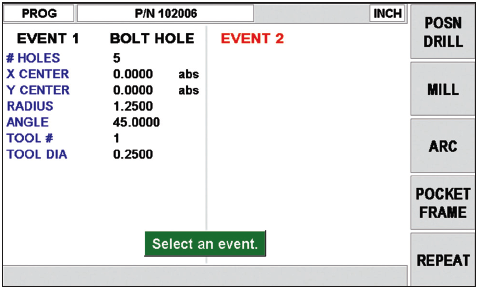

Powerful Canned Cycles

- Position

- Drill

- Bolt Hole

- Mill

- Arc

- Face Mill

- Circle Pocket

- Rectangular Pocket

- Irregular Pocket

- Circular Pocket

- Rectangular Profile

- Irregular Profile

- Subroutine Repeat

- Subroutine Rotate

- Subroutine Mirror

- Copy Repeat

- Copy Rotate

- Copy Mirror

The All-New ProtoTRAK KMX!

- The best CNC we’ve ever made for knee mill applications

- Easy to learn and use with thoughtful features that make work easier

- Improved AGE® capability gives you the power of CAD for finding missing print data while you program!

- Outstanding graphics

- ProtoTRAK combination of price, features and ease of use

- Can handle anything from quick manual jobs to complex profiling

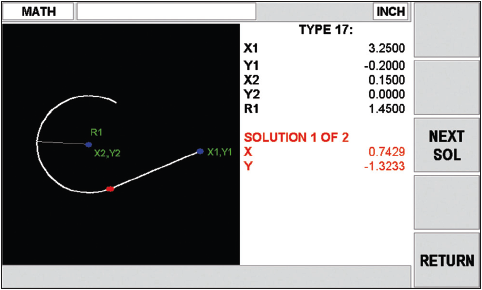

AGETM the Auto Geometry Engine

Program complex profiles easily with the powerful AGETM feature.

Enter the information you have and the AGETM will calculate missing

points for you while you program.

Advanced File Management

DRO Routines

The most useful features of a DRO are available in a crystal clear color display. While working manually in the DRO mode, let the servo motors do the most of the work by pressing the Power Feed and Jog buttons. When you need manual control, ball screws provide smooth, positive control while hand cranking.

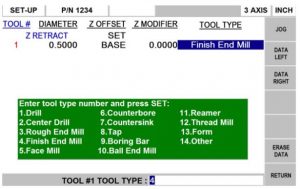

Programming

Program the ProtoTRAK EMX by making simple selections and answering prompts in plain English. Unlike conventional CNCs, you define only the part geometry; the ProtoTRAK EMX defines the tool path for you.

Part Graphics

While programming, simply press the LOOK key for color graphics of what you have programmed so far.

Program Storage

Handling programs is easy with the simple, clear choices of the ProtoTRAK. An internal flash drive lets you save hundreds of typical programs. A USB port is available to plug in a storage device for backing up programs and moving programs between ProtoTRAKs and computers. The optional USB thumb drive is convenient to use and comes configured to work with the ProtoTRAK.

Math Helps

Math Helps are available for you to quickly and easily calculate intersections, points of tangency, arc centers and more.

Learning the ProtoTRAK

Even if your people have never used a CNC before, they will be able to learn the ProtoTRAK in just a few hours. From the first day you own it, your people will discover that it is easier to make parts with a ProtoTRAK than it is to use manual machining methods. They’ll quickly find, like thousands of machinists before them, that the effort to learn the ProtoTRAK will pay off in job satisfaction.