Niigata HN50E-5X HN50E-5X 5-Axis Horizontal Machining Center (5-Axis HMC)

This 5-axis horizontal machining center features a rigid machine body.

Machine base of HN63E – a rigid boxway machine with excellent stability and great damping characteristics.

High torque spindle.

Rigid trunnion table for low frequency machining.

High load roller BRG and double-lead worm gear for A and B axes, high torque drive.

Perfect for machining titanium and other hard machining materials.

A variety of 5-axis machining support software.

Niigata HN63E-5X HN63E-5X 5-Axis Horizontal Machining Center (5-Axis HMC)

This 5-axis horizontal machining center features a rigid machine body.

Machine base of HN63E – a rigid boxway machine with excellent stability and great damping characteristics.

High torque spindle.

Rigid trunnion table and low frequency machining.

High load roller BRG and double-lead worm gear for A and B axes, high torque drive.

Perfect for machining titanium and other hard machining materials.

A variety of 5-axis machining support software.

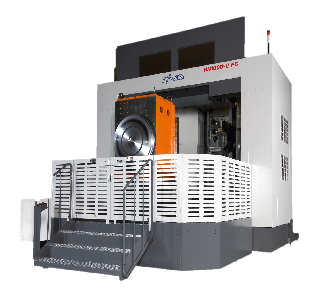

Niigata HN100D-II-FC HN100D-II-FC Multi-Tasking Horizontal Machining Center (HMC)

Multi-tasking horizontal machining center performs turning, facing, boring and milling, all in one machine and completely programmable.

Rigid & solid machine body.

Outstanding stability & vibration damping by thick machine base.

Long-term accuracy and rigidity by wide induction hardened boxways that are skillfully scraped by Niigata.

Largest work zone in its class.

Long stroke.

Wide machining range.

Standard facing head or twin facing tool head.

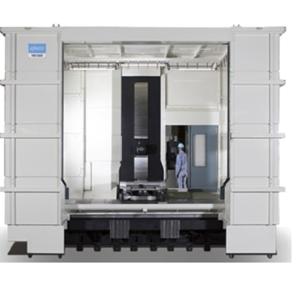

Niigata HN130D-FC HN130D-FC Multi-Tasking HMC with Largest Work Zone

Multi-tasking horizontal machining center (HMC) with largest work zone performs turning, facing, boring and milling, all in one machine and completely programmable.

Outstanding stability & vibration damping by thick machine base.

Long-term accuracy and rigidity by wide induction hardened boxways that are skillfully scraped by Niigata.

Largest work zone in its class.

Long stroke.

Wide machining range.

Standard facing head or twin facing tool head.

Niigata HN1600D-FC HN1600D-FC Multi-Tasking Horizontal Machining Center (HMC)

Multi-tasking horizontal machining center performs turning, facing, boring and milling, all in one machine and completely programmable.

Rigid & solid machine body.

Outstanding stability & vibration damping by thick machine base.

Long-term accuracy and rigidity by wide induction hardened boxways that are skillfully scraped by Niigata.

Largest work zone in its class.

Long stroke.

Wide machining range.

Standard facing head or twin facing tool head.

Niigata HN100D-II-BAR HN100D-II-BAR Horizontal Machining Center with Bar/Quill Style Spindle

Horizontal machining center with bar/quill style spindle features a spindle bar diameter of 130mm.

Bar/Quill machining is strongly supported by Niigata HN series rigid machine body.

Solid and tough machine body.

Outstanding stability & vibration damping by thick machine base.

Long-term accuracy and rigidity by wide induction hardened boxways that are skillfully scraped by Niigata.

High-torque spindle with gear drive.

Niigata HN1250-S-BAR HN1250-S-BAR Hybrid Machining Center with Boring Function

A hybrid machining center with boring function.

Harmony of rigidity from boxway system (Y axis) and high productivity from roller guide (X,Z axis).

Rapid traverse 41m/min for ultra heavy work.

Outstanding stability & vibration damping by thick machine base.

Spindle diameter ɸ 130.

Solid machine base of HN series suitably supports powerful boring machining.

Niigata HN1600-S-BAR HN1600-S-BAR HMC with Largest Work Envelope in Its Class

HMC with largest work envelope in its class.

Harmony of rigidity from boxway system (Y axis) and high productivity from roller guide (X,Z axis).

Rapid traverse 30m/min for ultra heavy work.

Outstanding stability & vibration damping by thick machine base.

Hi-torque heavy duty spindle.

Wide machining range.

Niigata HN1000-S-BAR HN1000-S-BAR Hybrid HMC with Boring Function, Long Stroke

A hybrid HMC with boring function, long stroke.

Harmony of rigidity from boxway system (Y axis) and high productivity from roller guide (X,Z axis).

Rapid traverse 41m/min for ultra heavy work.

Outstanding stability & vibration damping by thick machine base.

Spindle diameter ɸ 130, Bar/Quill stroke 535 mm.

Solid machine base of HN series suitably supports powerful boring machining.

Wide machining range.