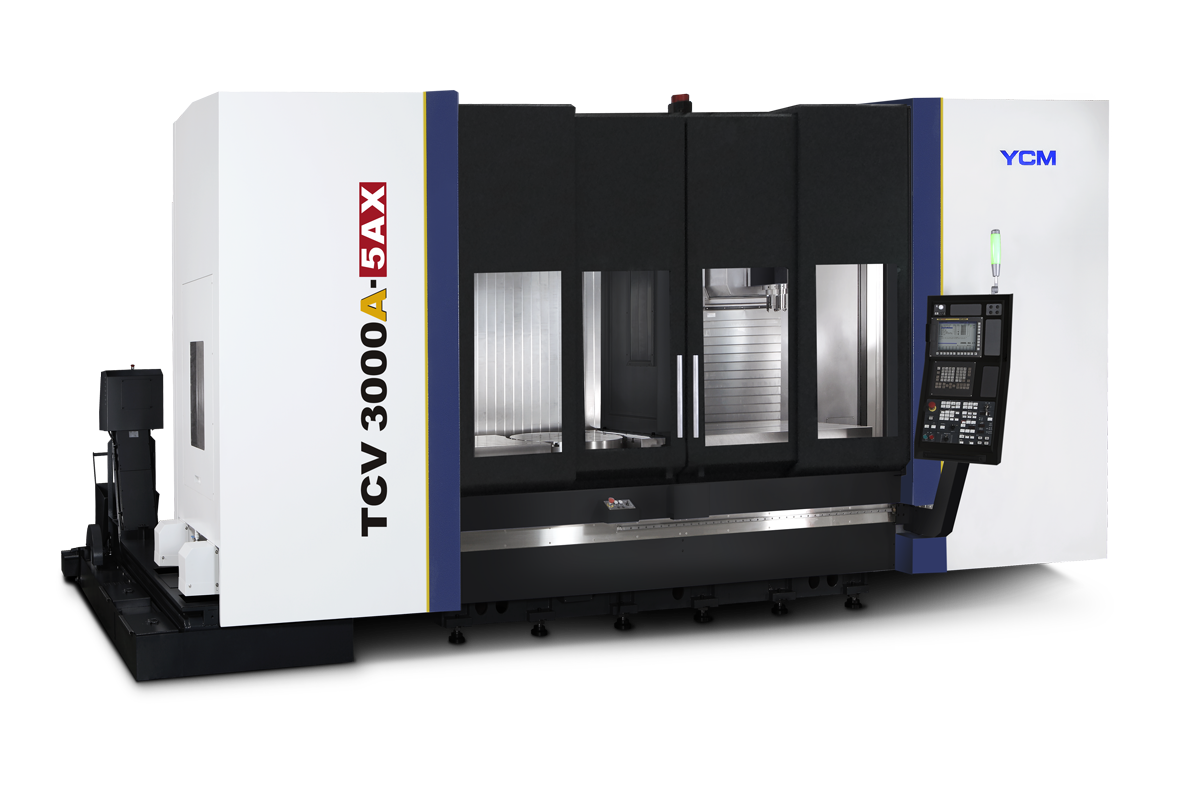

| Model | TCV3000A-5AX |

|---|---|

| Work Table mm | 3,500 x 800 |

| X-axis Travel mm | 3,000 |

| Y-axis Travel mm | 800 |

| Z-axis Travel mm | 800 |

| Spindle Speed rpm | 12,000 (15,000 / 16,000 [Big Torque] ) |

| Spindle Taper | BBT40 (HSK-A63) |

| Spindle Power kW | 25 ( 25/50 )[HDH] |

| Tool Magazine Capacity (Opt.) | 40 (80) |

| Machine Weight kg | 24,700 |

YCM TCV3000A-5AX

- Wide span design of machine structure.

- High efficiency traveling column design.

- Large delta machine column and base ensure highest stability.

- With FEM analysis.

- With stepped design and 6 slider blocks on X-axis ensure the ultra reliable axial movement.

- Large working area is ideal for large and long workpieces machining.

- With the installation of dividing wall in the working area, both long and complex parts can be manufactured in the same machine.

- High precision roller type guideways on 3 axes

- Capable of reaching up to 40 m/min rapid feedrate.

- Circulated cooling system design on X-axis ensures stable temperature and optimal accuracy.

- Centroid driven on X-axis to reduce vibration during movement.

- No counter weight design on Z-axis that lowers vibration while machining and greatly improves surface roughness.

- The guide blocks support tool magazine to ensure smooth and stable movement.

- Reliable ATC system: Tool magazine with 40T. (80T opt.)

- speed (B-axis): 33.3 rpm

- Swivel angle (B-axis): ±110° / ±120° (Big torque opt.)

- speed (C-axis): 50 rpm (FANUC opt.) / 90 rpm (HEIDENHAIN std.)

- Positioning accuracy (C-axis): <10 sec.

- The YCM in-house built-in spindle effectively lowers vibration, providing the best surface performance. Meanwhile, it prolongs lifespan of spindle and tools during heavy cutting.

- BBT40 double contact spindle taper greatly enhances machining accuracy.

- Up to 16,000 rpm spindle, 50 kW 67 HP outputs and Swivel angle 120°, best for heavy cutting. (opt.)

- Tool shank: HSK A63 (opt.)