| Model | TC26 |

|---|---|

| Machining Capacity | |

| Max. Turning Diameter (mm) | ø470 |

| Max. Turning Length (mm) | 647 (638) |

| Main Spindle | |

| Chuck Size | 10(12) |

| Spindle Nose | A2-8 |

| Hole Through Spindle (mm) | ø88 |

| Hole Through Draw Bar (mm) | ø78 |

| Spindle Speed (rpm) | 10" L: 8~195~783H: 40~1,007~4,000 12" L: 8~195~783H: 40~1,007~2,500 |

| Sub Spindle | |

| Travel | |

| X-axis Travel (mm) | 250 |

| Z-axis Travel (mm) | 700 |

| Feedrate | |

| "X - axis Rapid Feedrate / Cutting Feedrate" (m/min / mm/min) | 15 / 1~5,000 |

| "Z - axis Rapid Feedrate / Cutting Feedrate" (m/min / mm/min) | 20 / 1~5,000 |

| Motor | |

| Main Spindle Motor (kW) | 11 / 15 |

| Turret | |

| Turret Type | Hydraulic Turret |

| Turret Capacity (Opt.) | 12T (8T) |

| Swing Over Turret (mm) | ø640 |

| Tailstock | |

| Quill Taper | MT-5 |

| Quill Stroke (mm) | 530 |

| Machine Weight kg | 4,400 |

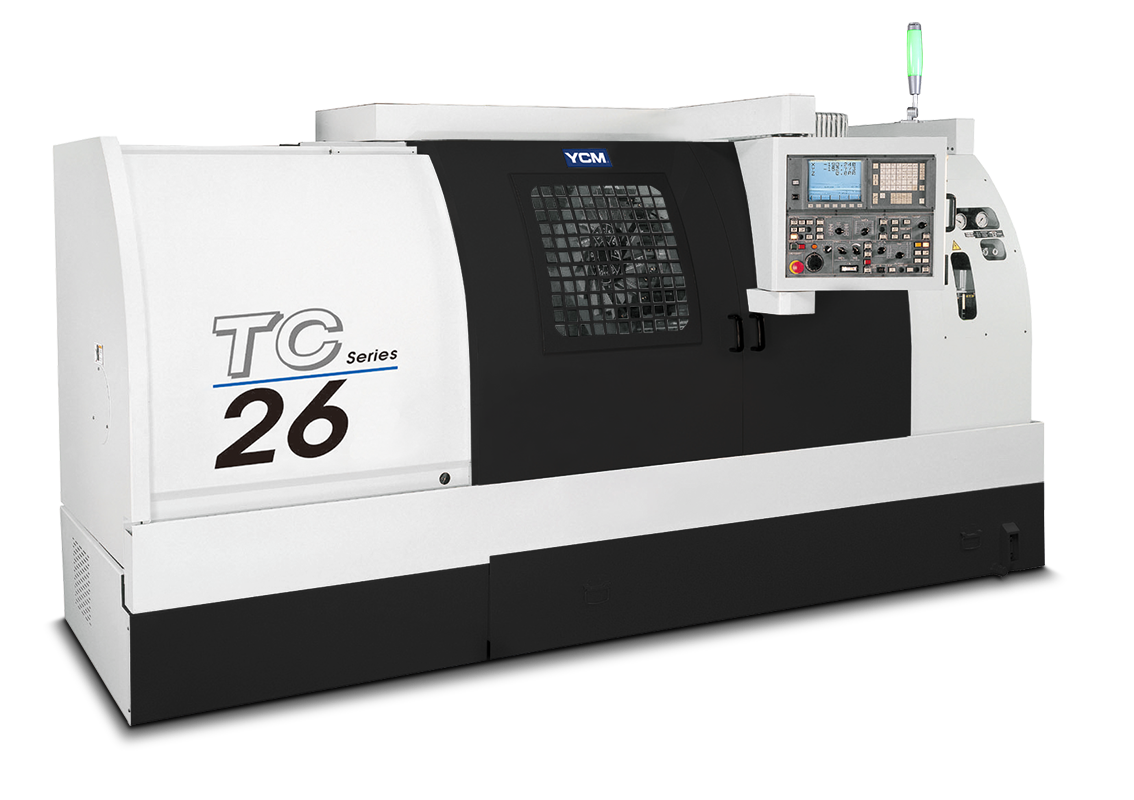

YCM TC26

- The 12-station turret index is done by absolute detection to reduce tool selection mistake.

- The powerful turret with large diameter curvic coupling offers high precision and high rigidity in cutting performance.

- The spindle is equipped with high precision angular ball bearing and NN series bearing that provides high precision and rigidity working condition.

- The inner diameter of the bearing is ø120mm ø4.72″, and ø88mm ø3.46″ of the spindle through hole. ø78mm ø3.07″ of the drawbar through hole adapts large diameter bar stock jobs.

- The powerful spindle with built-in gears provides various speed transmissions. The max. output of torque reaches 74.5kgf-m 539 lb-ft, with 4,000rpm max. spindle speed.

- Material Removal Efficiency: 410cm3/min.

- Insert Depth: 8mm 0.31″

- Extremely Rigid One-piece 45° Slanted Bed Design

- Using “M” code commands the quill stroke of the programmable tailstock can be hooked with a hydraulic hook to the saddle carriage and slide along the Z-axis stroke.

- X/Z-axis guideways are well hardened and ground with Turcite-B to reduce the friction and offer utmost rigidity in cutting. The rapid feedrate of X/Z-axis is 15/20 m/min. 591/787ipm

- Hydraulic gauges, control values of chuck and tail stock, and the central lubrication system are installed at the front side; for easy adjustment and maintenance.

- This machine is equipped with high precision ball screws and connected with motor directly. The fixing design supports both ends; the design of pre-tensioned ball screws provides high rigidity, high precision, and low heat effect.

- The machine with auto-lubrication design ensures the accuracy throughout its life time.

- The slide ways of X/Z-axis and ball screws are lubricated. Built-in alarm will occurred when the lubrication oil is insufficient.