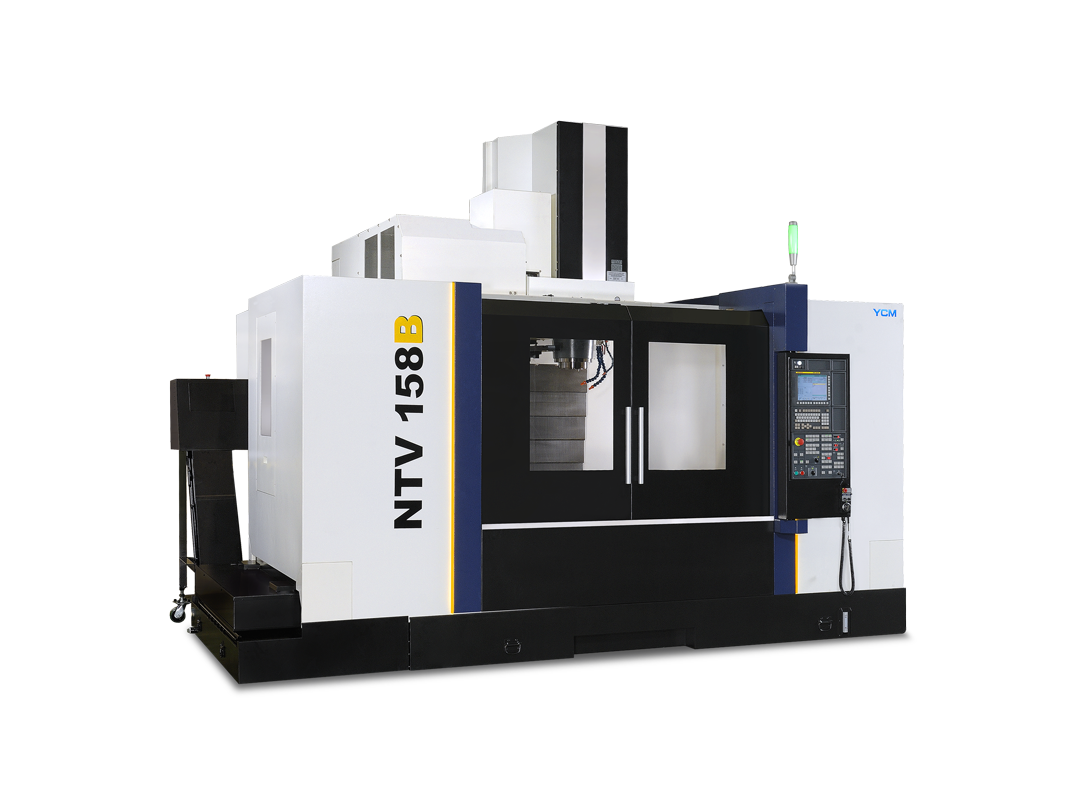

| Model | NTV158B |

|---|---|

| Work Table mm | 1,650 x 760 |

| X-axis Travel mm | 1,530 |

| Y-axis Travel mm | 762 |

| Z-axis Travel mm | 700 |

| Spindle Speed rpm | 10,000 ( 15,000 ) |

| Spindle Taper | BBT50(HSK-A100) |

| Spindle Power kW | 22 (30) |

| Tool Magazine Capacity (Opt.) | 24 (32/40) |

| Machine Weight kg | 15,500 |

YCM NTV158B

- With the unique T-base structure, the machine footprint can be reduced effectively.

- Overhang-free table movement is supported by high-rigidity base to ensure the best dynamic accuracy.

- Dual screw-type chip augers efficiently elevate chip removal rate.

- Massive MEEHANITE® casting through FEM analysis offers exceptional damping capacity.

- Reduces noise, backlash and vibration issues and maximizes spindle accuracy and life.

- YCM’s uniquely designed IDD Spindle ensures direct transmission and is proven to maximize both spindle and tool life under harsh working environment.

- The cooling system for spindle motor seat and spindle makes real time control of spindle temperature.

- The oil-air lubrication system ensures long-term high-speed operation.

- All axes are equipped with roller type linear guideways to ensure higher dynamic accuracy, durability and rigidity.

- Preload high precision ball screws are directly driven by servo motor will efficiently eliminate axial backlash and vibrations.

- X-axis with 6 guideway blocks fully supports the saddle and efficiently releases loading from the table.

- Y-axis is designed with 3 guideways maintaining exceptional dynamic accuracy.

- The casting rigidity is enhanced through FEM analysis.

- Roller type guideways provides low friction which reduces energy waste.

- Increases the feedrate and acceleration/deceleration.

- High response axial control provide smooth movement.

- Low inertia avoids vibration during high speed feedrate.

- Dual drive system on Z-axis elevates exceptional axial smoothness and machining efficiency, and ensures fine surface roughness.

- Up to 15,000 rpm (HSK A100) spindle is available to meet different machining demands.