| Model | NFT-2223 |

|---|---|

| X axis mm | 2200 |

| Y axis mm | 2300 |

| Z axis mm | 920 |

| Distance from Vertical Spindle Nose to Table mm | 85~1,005 |

| Distance from Horizontal Spindle center to Table mm | 335~1,255 |

| Table Dimension mm | Ø1,800 |

| Table Load (Central Region) kg | 3000 |

| Min division accuracy degree | 0.001 |

| Rated Torque Nm | 2040 |

| Max. Torque Nm | 3800 |

| Braking Torque Nm | 10210 |

| Max. Cutting Torque under Braking Nm | 7000 |

| Tool clamping type | Auto-hydraulic clamping |

| Head clamping type | Fixed |

| C axis angle | Fixed |

| B axis angle degree | ±110゚ |

| B axis index degree | 1゚ |

| Indexing precision | ±0.03/300mm |

| Indexing function | Auto angle positioning (B axis) |

| Lubrication | Bearing oil-air lubrication |

| CTS function | Available for 20/50 bar. |

| Spindle cooling | Oil cooling circulation |

| Max. cutting Power kW | 26 |

| Spindle speed rpm | 4000 |

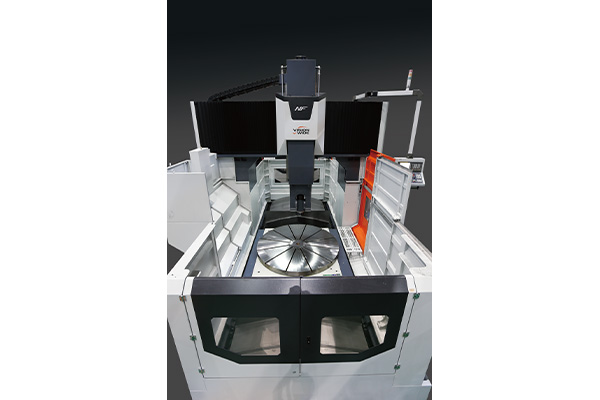

VISION WIDE NFT Series

NFT series inherits Vision Wide’s high structural rigidity product design. The addition of a rotary table makes it easier for the engineering, hydraulic, tire mold, turbine blade and all cylindrical workpiece machining.

| Standard Accessory & Function | Optional Accessory & Function |

|---|---|

| 1. FANUC 31iB controller | 1. 6,000 rpm box way type 2-step gear spindle |

| 2. 4,000 rpm box way type 2-step gear spindle | 2. Vertical type tool magazine 60 tools |

| 3. Ztravel 920mm | 3. Ztravel 1,020mm |

| 4. Spindle oil cooling device | 4. Oil skimmer |

| 5. Twin hydraulic cylinders with pressured Nitrogen assistance counterweight System | 5. Z-axis retract function at power failure |

| 6. Rotary Table 1,800mm | 6. Enclosed sheet metal guard with roof |

| 7. Centralized auto lubrication system | 7. Helical bladed screw conveyor on table sides |

| 8. Independent lubrication oil collector | 8. Chip cart |

| 9. Air blast through spindle | 9. XYZ-axis linear scale |

| 10. Wash gun and pneumatic interface | 10. 3-axis independent manual pulse generator |

| 11. Cutting fluid cooling system | 11. Auto tool length measurement |

| 12. Vertical type tool magazine 40 tools | 12. Auto workpiece coordinate measurement |

| 13. Enclosed sheet metal guard without roof | 13. Air conditioning for electrical cabinet |

| 14. Swiveling arm type operation panel | 14. Overhead pendulum type operation panel |

| 15. Screw type chip conveyor on table sides | 15. Anti-collision and proecess simulation software |

| 16. Caterpillar type chip conveyor | 16. Remote monitoring software-Profession |

| 17. Heat exchanger for electrical cabinet | 17. Auto warm up |

| 18. Working lamp | 18. Transformer |

| 19. Operation cycle finish and alarm light | |

| 20. Movable manual pulse generator | |

| 21. Footswitch for tool clamping | |

| 22. RJ45 interface | |

| 23. XYZ-axis absolute pulse coder feedback | |

| 24. XYZ-axis travel hard limits protection | |

| 25. Auto power off | |

| 26. Spindle cutting load software protection | |

| 27. Remote monitoring software (FANUC) | |

| 28. Vision Wide FX graphical user interface | |

| 29. Foundation pads and bolts kits | |

| 30. Adjustment tool and tool kits | |

| 31. Technical manuals |