| Machine Specs | |

|---|---|

| Table size | 44.09″ x 19.69″ |

| Travel (X, Y, Z axis) | 40″ x 20″ x 20″ |

| Travel (X, Y, Z axis) with soft limits | 40.35″ x 20.24″ x 20.24″ |

| Rapid traverse X, Y, Z | 1,000 IPM |

| Cutting max. speed X, Y, Z | 1,000 IPM |

| T-slots (number x width x pitch) | 5 x .709″ x 3.937″ |

| Maximum weight of workpiece | 1,760 lbs |

| Height of table from bottom of floor*** | 38″ |

| Min. spindle nose to table distance **** | 3.5″ |

| Max. spindle nose to table distance **** | 23.50″ |

| Distance of ATC arm to table | 20″ |

| Min. machine height *** | 93.5″ |

| Max. machine height (head all the way up) *** | 108″ |

| Overall width of machine with side doors open and chip conveyor (no chip bin) | 177″ |

| Overall length of machine with electrical cabinet fully open 180° | 150.25″ |

| Footprint of machine with chip conveyor & coolant tank in place. Pendant not rotated 90° (width x length) | 144″ x 112″ |

| Weight net / shipping | 9,900 lbs / 10,250 lbs |

| Spindle Specs | |

| Spindle taper | 40 Taper |

| Spindle speed range | 10 - 12,000 RPM |

| Spindle nose diameter | 3″ |

| Tool clamping force (90 psi) | 1,500 lbs |

| Tool holder type | CAT 40 standard BT 40 optional (must change ATC arm) |

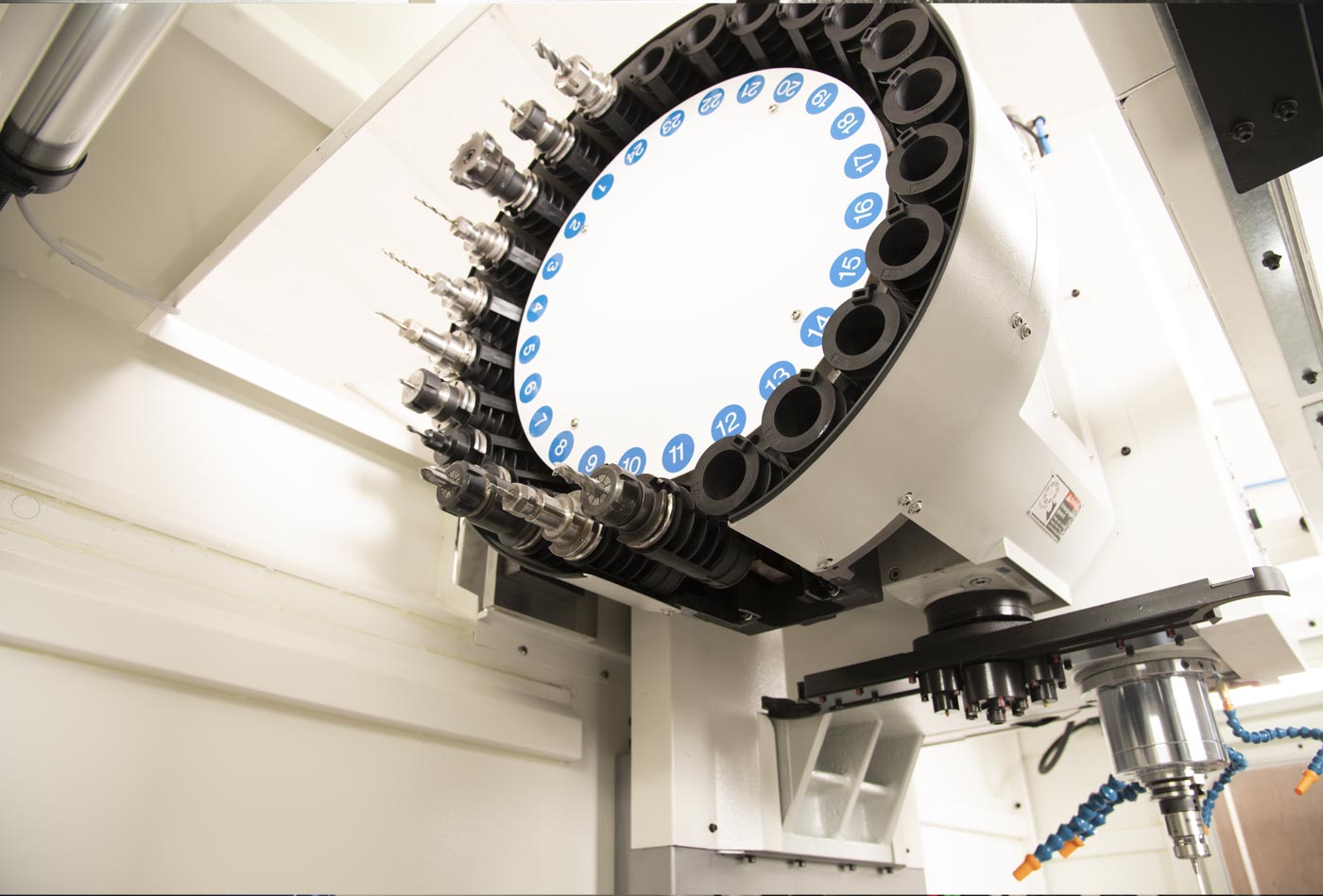

| ATC tool capacity | 24 |

| Maximum tool weight (incl. holder) | 17.6 lbs |

| Maximum tool diameter | 3.07″ |

| ATC arm tool change time | 2.5 seconds |

| Spindle motor HP - peak | 41.5 HP |

| Spindle motor HP - continuous (480V) | 20.1 HP |

| Spindle center to spindle head casting face | 18.25″ |

| Spindle cooler oil capacity | ~1 gallon |

| Power Requirements | |

| Power requirements - standard | 480V (432-528V is acceptable), 3P, 41A |

| Power requirements - optional | 208V with transformer option (200-240V is acceptable), 3P, 94A |

| Coolant System | |

| Tank capacity | 60 gallons |

| Pressure and volume | 8.7 gpm @ 42 psi |

| Pump and wash power | 750 watts |

| Coolant wash pump | 750 watts |

| CTS pump (Coolant Through Spindle) | 3 KW / 4 HP |

| CTS pressure | 319 psi |

| Air Requirements | |

| Air - CFM, SCFM (at 90 PSI) | 2.5 CFM, 18 SCFM |

| Air quality | Air dried/water separator upstream of VMC |

| Lubrication Requirements | |

| Lubrication pump capacity | 2 liters |

| Lube Oil Type | ISO 32 or 10 W |

Specifications subject to change.

** Must remove ATC motors and all sheet metal attached to top of electrical cabinet. The cable way for Z axis also needs to be removed. The lifting point on the electrical cabinet is now the highest point.

*** Height changes slightly based on how machine is leveled on leveling screws.

**** Can vary slightly due to soft limit settings.