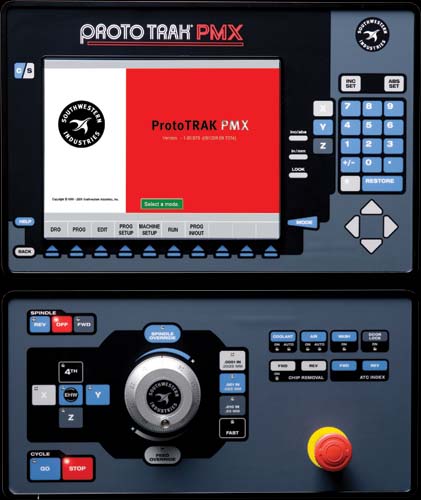

Description

DRO Mode Features

- Incremental and absolute dimensions

- Jog with selectable feed rates

- Powerfeed X, Y or Z

- Servo return to 0 absolute

- Go To Dimensions from convenient reference

- Spindle speed setting with manual override

- Selectable handwheel resolution

- Convenient choice of dimensional references: Machine Home, Part Zero, Abs Zero Ball lock locations

Program Mode Features

- Auto Geometry Engine

- Geometry-based programming

- Tool Path programming

- Scaling of print data

- Multiple fixture offsets

- Programming of Auxiliary Functions

- Event Comments

- Three-axis Geometry conversational programming

- Incremental and absolute dimensions

- Automatic diameter cutter comp

- Circular interpolation

- Linear interpolation

- Look–graphics with a single button push

- List step – graphics with programmed events displayed

- Alphanumeric program names

- Program data editing

- Program pause

- Conrad – automatic corner radius

- Programmable spindle speeds

- Math helps with graphical interface

- Auto load of math solutions

- Tool step over adjustable for pocket routines

- Pocket bottom finish pass

- Selectable ramp or plunge cutter entry

- Subroutine repeat of programmed events

- Nesting

- Rotate about Z axis for skewing data

- Mirror of programmed events

- Copy

- Copy rotate

- Copy mirror

- Tool data entry in event programming

- Selectable retract in Bore operations

Auxillary Functions

- Coolant on/off

- Air on/off

- Pulse indexer

- Part change table position

Canned Cycles

- Position

- Drill

- Bolt Hole

- Mill

- Arc

- Circle pocket

- Rectangular pocket

- Irregular Pocket

- Circular profile

- Rectangular profile

- Irregular Profile

- Circle Island

- Rectangular Island

- Irregular Island

- Helix

- Thread milling

- Engrave

- Tapping

- Face Mill

Edit Mode Features

- Delete events

- Erase program

- Spreadsheet editing

- Global data change

- G-Code editor

- Clipboard to copy events between programs

- Move between subprograms in a master program

Program Set Up Mode Features

- Program diagnostics

- Advanced tool library

- Tool names

- Tool length offset with modifiers

- Tool path graphics with adjustable views

- Program run time estimation clock

- Convenient part/fixture management screen

- Fixture offsets

- Part offsets within fixture

- Convenient manual tool handling when tools required exceed ATC capacity

- Photo storage and display

- Notes

- Z Safety Dimension to prevent crashes

- Tool Crib

- Tool by Tool or Part by Part run strategy

- Convenient Tool Reconciliation between programs and ATC

- Convenient ATC capacity

Machine Set Up Mode Features

- Advanced diagnostic routines

- Software travel limits set in the factory

- Prompted Tool loading and ATC Management

- Checklist to assure nothing is forgotten

- Single key press to get to step needing attention

Run Mode Features

- TRAKing

- 3D CAM file program run

- 3D G code file run with tool comp

- Real time run graphics with tool icon

- Countdown clock for total part cycle time or manual tool change

- Error alarms prevent Run when set up steps are skipped

- Work on Staged programs while Current program runs

Program In/Out Mode Features

- CAM program converter

- Converter for prior-generation ProtoTRAK programs

- DXF/DWG file converter (Optional)

- Selection of file storage locations

- Automatic file back-up routine

- Preview graphics for unopened files

- Networking

- Create Master routine for combining programs

- Transfer of Staged program to Current

- Tool reconciliation for Master Programs

Control Options The DXF File Converter Option

- Import and convert CAD data into

- ProtoTRAK programs

- DXF or DWG files

- Chaining

- Automatic Gap Closing

- Layer control

- Easy, prompted process you can do right at the machine

CAM Out Converter Option

- Save ProtoTRAK files as CAM files for running on different controls

- 4th Axis Option

- True 4-axis interpolation.

Includes: indexer, tailstock and fixture plate.