- Max. grinding length-longitudinal: 610 mm (24”); Max. grinding width-crosswisw 305 mm (12”);

Distance between table to spindle centerline 590 mm (23.2”); Max. table loading 420 kg (926 lbs.). - Control system: SMART iControl (PC based) with HMI and iMCS networking connectivity for impoved production.

- Table size: 300 x 600 mm (11.8” x 23.6”); Table speed: 0~25,000 mm/min (0~82 fpm);

Max. table travel: 710 mm (28”). - Ballscrew and servo motor drive: 3-Axes; Sprindle motor: 11 kW (15 HP)

- Transverse movment (Z): Max. travel 3520 mm (13.7”); Feed speed 0~4,000 mm/min (0~13 fpm)

- Wheelhead elevation (Y): Max. travel 450 mm (17.7”); Feed speed 0~3,800 mm/min (0~12.5 fpm)

- Accuracy: Position accuracy: 0:005 mm (.00019”); Repeatability accuracy: 0.003 mm (.0001”)

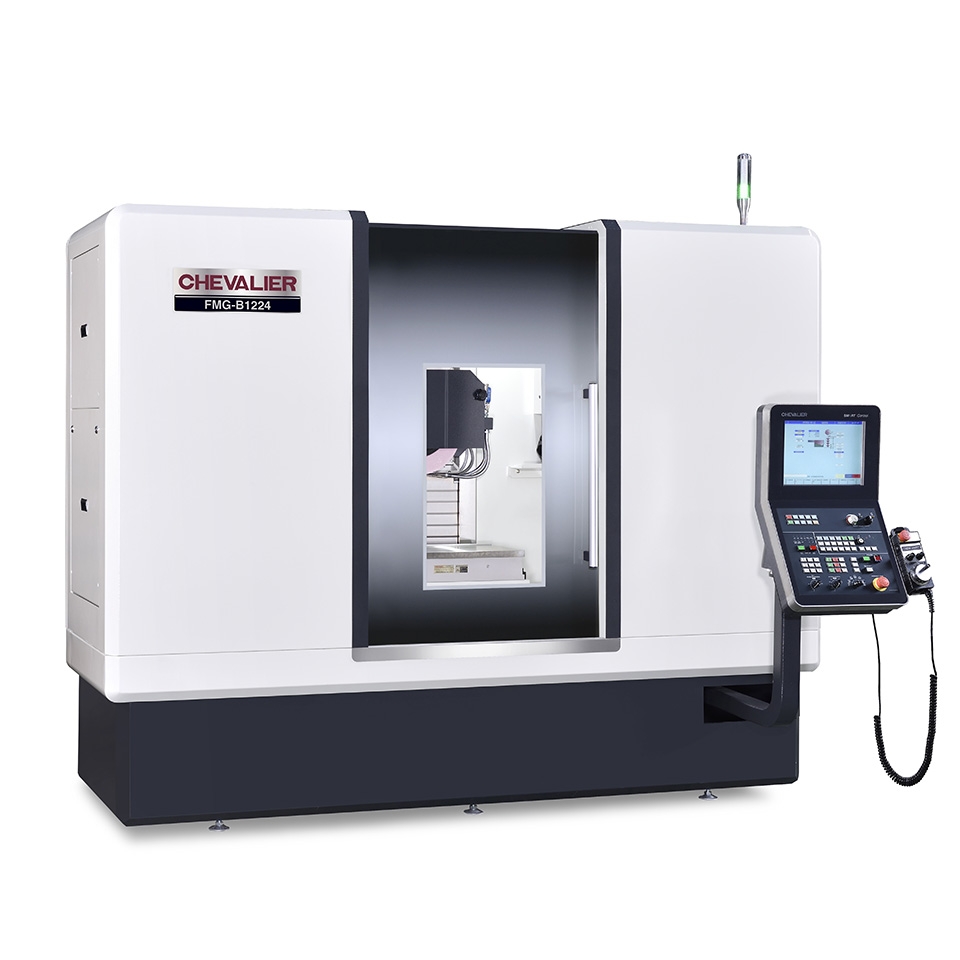

Chevalier FMG-B1224

Traveling Column Grinder

- Chevalier’s R&D team used precision analysis to design a rigid machine structure that incorporates a traveling column to effectively improve stability for high grinding efficiency and reliable machining accuracy.

- To prevent vibration and ensure machining accuracy, the high-strength rigid design is built to withstand the maximum force caused by deformation.

- By analyzing processing requirements and experience, we optimized the machine’s structural integrity to ensure high performance.

- The SMART iControl’s conversational programming eliminates complicated programming codes and computing force enhances the HMI (Human Machine Interface) for greater precision.

- The FMG-B1224 easily adapts to future needs for job shops, medical, automotive, semiconductor and aerospace.

- FMG-B1224 offers more value for your investment.